Able Hardware is a China-based factory specializing in engineered wire products for OEM and retail programs. We build to print and support design-for-manufacture for refrigerator wire shelves, freezer baskets with integrated handles, ワイヤーファンガード, and retail/warehouse wire shelving with configurable accessories. As a direct manufacturer, we provide OEM/ODM custom service from prototype to SOP, supported by export-ready QA and packaging.

Explore our wire product range and related services: 炭素鋼線材, ワイヤーファンガード, 冷蔵庫ワイヤーシェルフ, そして ワイヤーフリーザーバスケット.

Why this solution for OEM quality & cost efficiency

- Strong, lightweight grids deliver high stiffness-to-weight for shelves, バスケット, and guards.

- Process fit for scale: resistance spot welding at intersections + automated forming keeps takt time low and dimensional repeatability high.

- Finish durability: 粉, vinyl dip, zinc plating to ASTM B633, and e-coat options balance cost vs. corrosion performance.

- Documented QA: dimensional reports, FAI, PPAPの基本, and traceability accelerate approvals and audits.

Typical industries & applications

- Appliance: refrigerator/freezer wire shelves, door racks, freezer baskets, fan guards.

- Retail & 画面: modular wire shelving, 仕切り, label holders, and hanging accessories.

- Industrial & warehousing: durable wire shelving, guards, and welded add-ons for carts and storage.

- Equipment/OEM: custom protective guards and formed wire frames with interface plates.

技術的特性

材料, wire diameters & load categories (UDL)

- 材料: low-carbon steel wire (CRS), galvanized steel wire, およびステンレス鋼 304/316 on request.

- Typical diameters: ~2.0–10.0 mm. Common shelf/basket grids use 3.0–6.0 mm primaries with smaller crosswires to tune UDL and weight.

- Load categories: designed around UDL per shelf/basket. We optimize wire gauge, span, and rib layout to meet target loads with minimal mass.

仕上げ & corrosion/adhesion performance (targets by agreement)

- パウダーコーティング (RAL/Pantone equivalent) for appliance-grade appearance and durability.

- Vinyl/plastic dip for impact resistance and quiet handling.

- 亜鉛メッキ に ASTM B633 (service class by agreement), または 電子コート for even coverage on complex forms.

- クロムメッキ only when specified.

- Performance targets (典型的な):

- Finish adhesion: ASTM D3359

- Wear resistance: ASTM D4060

- 耐食性 (neutral salt spray): ISO 9227 Targets are agreed per project and validated via pre-production runs.

制限事項 & alternatives (brief, if any)

For very high loads or long spans, consider thicker primaries, closer crosswire spacing, auxiliary ribs, or hybrid designs with laser-cut plate stiffeners. Where hygiene or aggressive chemicals dominate, upgrade to stainless 304/316.

製造オプション

Processes (wire forming → spot welding → light CNC → finishing)

- CNC wire forming/bending with accurate radii and repeatable geometry.

- Trimming/deburring for safe edges.

- Resistance spot welding for intersections; MIG/TIG for frames, handles, and plate interfaces.

- Light CNC (tapping, slots, and holes) on mounting plates or brackets as specified.

- 仕上げ per spec: 粉, vinyl dip, zinc to ASTM B633, 電子コート. See 仕上げ.

Supported tolerances (ISO 2768) & interface plates/brackets

- General tolerances: ISO 2768-m unless otherwise specified.

- Thermal cut quality (if plates): ISO 9013.

- Optional 三次元測定機 for critical interfaces. Datum strategies and gauge plans can be aligned to your drawing set.

種類 & ジオメトリ

Refrigerator wire shelves, freezer baskets, fan guards

- Refrigerator wire shelves: tailored grid patterns, front/back edges, and corner treatments; snap-fit or screw-on plate interfaces.

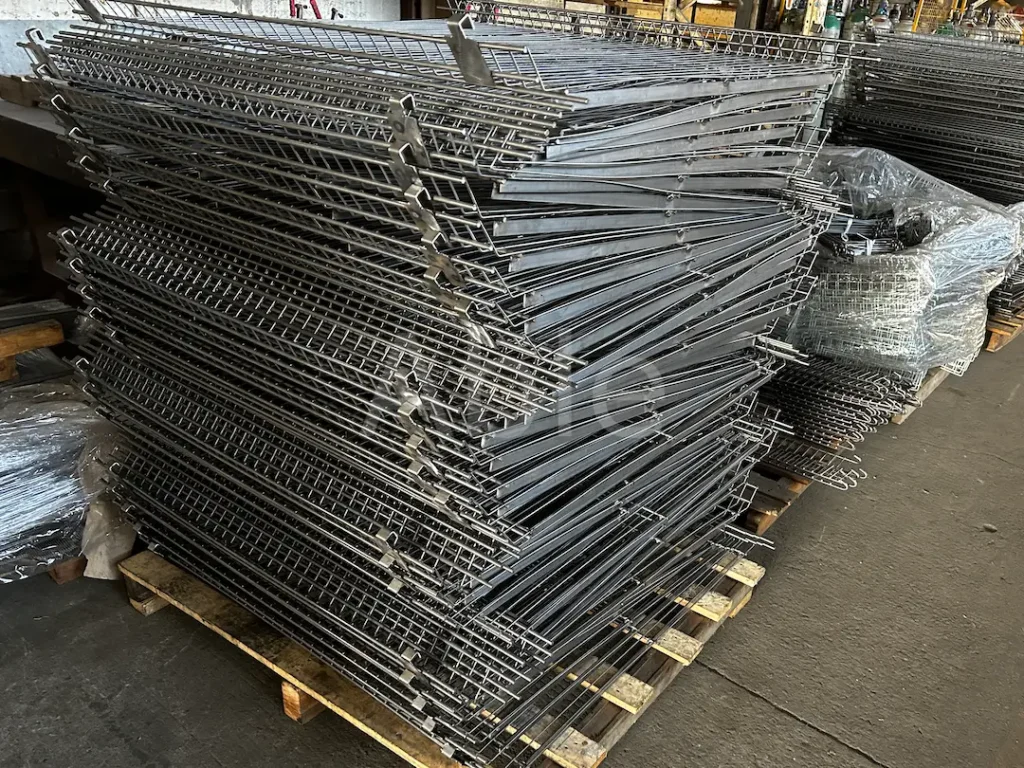

- Freezer baskets: stackable profiles, rolled rims, integrated handles; smooth edges for safe loading.

- ワイヤーファンガード: custom outer diameter, ring spacing, and blade-pitch compatibility; multi-point mounting plates.

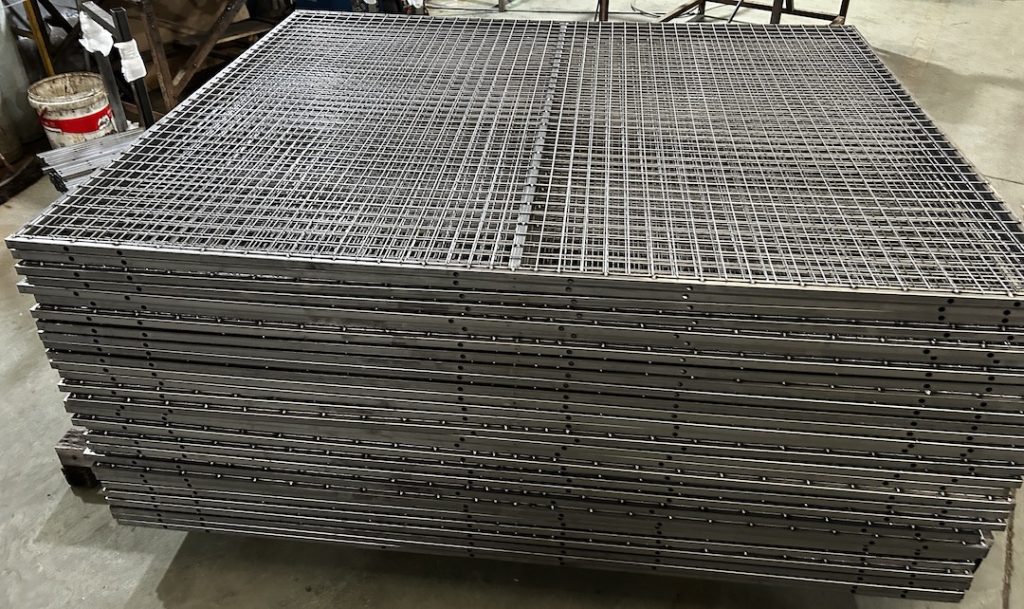

Retail/warehouse wire shelving & configurable accessories

- Modular shelves: optimized rib spacing for UDL targets; protective end caps and label features available.

- Accessories: 仕切り, hangers, product stops, and identification tabs built to drawing; coated for appearance and corrosion control. See the full category at Products → Wire.

品質 & テスト

私たちが検証すること (dimensional, finish tests, UDL checks) とドキュメント

- Dimensional: wire diameter, pitch, overall L×W×H, 平坦度, and bracket/plate locations.

- Load/UDL: sample shelf/basket deflection vs. target load; pass/fail per agreed criteria.

- Finish: adhesion (ASTM D3359), 着る (ASTM D4060), 腐食 (ISO 9227).

- ドキュメンテーション: COA, dimensional reports, FAI, PPAP (agreed list), material/finish traceability; オプション 三次元測定機 records.

Packaging & Shipping

KD/flat-pack, labeling, ISPM-15 pallets/crates; assembly guides

- KD/flat-pack wherever possible to minimize freight volume.

- Edge/paint protection with sleeves and guards.

- Barcode/labeling by SKU or kit; scan-ready carton IDs.

- Export pallets/crates に ISPM-15 with moisture protection.

- Assembly guides and hardware kitting (when specified). Learn more at Packaging & Shipping.

価格設定 & リードタイム

Moq, sample policy, 示唆的なコスト要因 (厳しい価格はありません)

- Lead-time model: prototype → tooling/fixture sign-off → SOP; production via releases/blanket orders.

- Moq: aligned to coating line/electro-plating rack capacity and packing economics.

- Indicative cost drivers: 材料 (CRS vs. galvanized vs. 304/316), wire diameter and grid density, number of welds, added plates/handles, finish type and thickness, labeling/kitting, and export packing.

- Samples: off-tool samples prior to SOP; design tweaks can reduce cost and cycle time. Request a cost-down review via Laser Cutting & CNC Machining for hybrid plate-and-wire options.

規格 & コンプライアンス

関連する規格/認証 & 提供されたドキュメント

- ISO 2768-m general tolerances; ISO 9013 (thermal cut plate features).

- ASTM B633 亜鉛メッキ; ASTM D3359 adhesion; ASTM D4060 着る; ISO 9227 neutral salt spray.

- Delivery with COA, material/finish traceability, dimensional reports, FAI, and PPAP basics (as agreed).

よくある質問

What materials do you support?

Low-carbon steel, 亜鉛メッキ鋼, and stainless 304/316 upon request for demanding environments.

What wire diameters are typical?

Approximately 2.0–10.0 mm overall; shelves and baskets commonly use 3.0–6.0 mm primaries with smaller crosswires.

Which coatings are available?

Powder, vinyl/plastic dip, zinc plating to ASTM B633, and e-coat. Chrome is available only when specified.

How do you define load capacity?

We design to a UDL target set during DFM. Deflection and safety margin are validated on pre-production parts.

What tolerances do you work to?

General tolerances per ISO 2768-m unless specified. We follow your drawing for welded and plate features; CMM optional.

What QA documents can you provide?

COA, dimensional reports, FAI, PPAPの基本, and traceability for materials and finishes.

What is the usual MOQ and lead time?

MOQ depends on finish line setup and packing efficiency. Lead time follows prototype → tooling sign-off → SOP; schedules improve with blanket orders.

How are products packed for export?

KD/flat-pack with edge protection, barcode labeling, そして ISPM-15 pallets/crates. Assembly guides included when required.

What do you need for an RFQ?

2D/3D drawings, target UDL, material/finish, quantity tiers, testing/standards, パッケージング, and delivery terms.

Call to Action

図面をアップロードする & get a quote today

Send drawings (STEP/DWG/PDF), target UDL and finish, quantity tiers, and packaging needs. We’ll return DFM notes, a quotation range, and a pilot schedule. 図面をアップロードする / 見積もりを取得する

引用を要求

もっと カスタムワイヤー製品: