Able Hardware is a China-based factory specializing in engineered wire products for OEM and retail programs. We build to print and support design-for-manufacture for refrigerator wire shelves, freezer baskets with integrated handles, Draht-Lüfterschutz, and retail/warehouse wire shelving with configurable accessories. As a direct manufacturer, we provide OEM/ODM custom service from prototype to SOP, supported by export-ready QA and packaging.

Explore our wire product range and related services: Walzdraht aus Kohlenstoffstahl, Drahtlüfterwache, Kühlschrank-Drahtregale, und Gefrierkörbe aus Draht.

Why this solution for OEM quality & Kosteneffizienz

- Strong, lightweight grids deliver high stiffness-to-weight for shelves, Körbe, and guards.

- Process fit for scale: resistance spot welding at intersections + automated forming keeps takt time low and dimensional repeatability high.

- Finish durability: Pulver, vinyl dip, Zinkbeschichtung nach ASTM B633, and e-coat options balance cost vs. corrosion performance.

- Documented QA: Dimensionsberichte, Fai, PPAP -Grundlagen, and traceability accelerate approvals and audits.

Typische Branchen & Anwendungen

- Gerät: refrigerator/freezer wire shelves, door racks, freezer baskets, fan guards.

- Einzelhandel & Anzeige: modular wire shelving, Trennwände, Etikettenhalter, and hanging accessories.

- Industriell & warehousing: durable wire shelving, Wachen, and welded add-ons for carts and storage.

- Equipment/OEM: custom protective guards and formed wire frames with interface plates.

Technische Eigenschaften

Materialien, wire diameters & load categories (UDL)

- Materialien: low-carbon steel wire (CRS), galvanized steel wire, und Edelstahl 304/316 on request.

- Typical diameters: ~2.0–10.0 mm. Common shelf/basket grids use 3.0–6.0 mm primaries with smaller crosswires to tune UDL and weight.

- Load categories: designed around UDL per shelf/basket. We optimize wire gauge, span, and rib layout to meet target loads with minimal mass.

Oberflächen & corrosion/adhesion performance (Ziele nach Vereinbarung)

- Pulverbeschichtung (Ral/Pantone -Äquivalent) for appliance-grade appearance and durability.

- Vinyl/plastic dip for impact resistance and quiet handling.

- Verzinkung zu ASTM B633 (service class by agreement), oder E-Coat for even coverage on complex forms.

- Verchromt only when specified.

- Performance targets (typisch):

- Finish adhesion: ASTM D3359

- Wear resistance: ASTM D4060

- Korrosionsbeständigkeit (neutral salt spray): ISO 9227 Targets are agreed per project and validated via pre-production runs.

Einschränkungen & Alternativen (knapp, wenn überhaupt)

For very high loads or long spans, consider thicker primaries, closer crosswire spacing, auxiliary ribs, or hybrid designs with laser-cut plate stiffeners. Where hygiene or aggressive chemicals dominate, Upgrade auf rostfrei 304/316.

Fertigungsoptionen

Processes (wire forming → spot welding → light CNC → finishing)

- CNC wire forming/bending with accurate radii and repeatable geometry.

- Trimming/deburring for safe edges.

- Resistance spot welding for intersections; ICH/DU for frames, Griffe, and plate interfaces.

- Light CNC (Tippen, Schlüssel, and holes) on mounting plates or brackets as specified.

- Abschluss per spec: Pulver, vinyl dip, zinc to ASTM B633, E-Coat. Sehen Abschluss.

Unterstützte Toleranzen (ISO 2768) & interface plates/brackets

- Allgemeine Toleranzen: ISO 2768-m unless otherwise specified.

- Qualität des thermischen Schnitts (if plates): ISO 9013.

- Optional CMM for critical interfaces. Datum strategies and gauge plans can be aligned to your drawing set.

Typen & Geometrie

Refrigerator wire shelves, freezer baskets, fan guards

- Refrigerator wire shelves: tailored grid patterns, front/back edges, and corner treatments; snap-fit or screw-on plate interfaces.

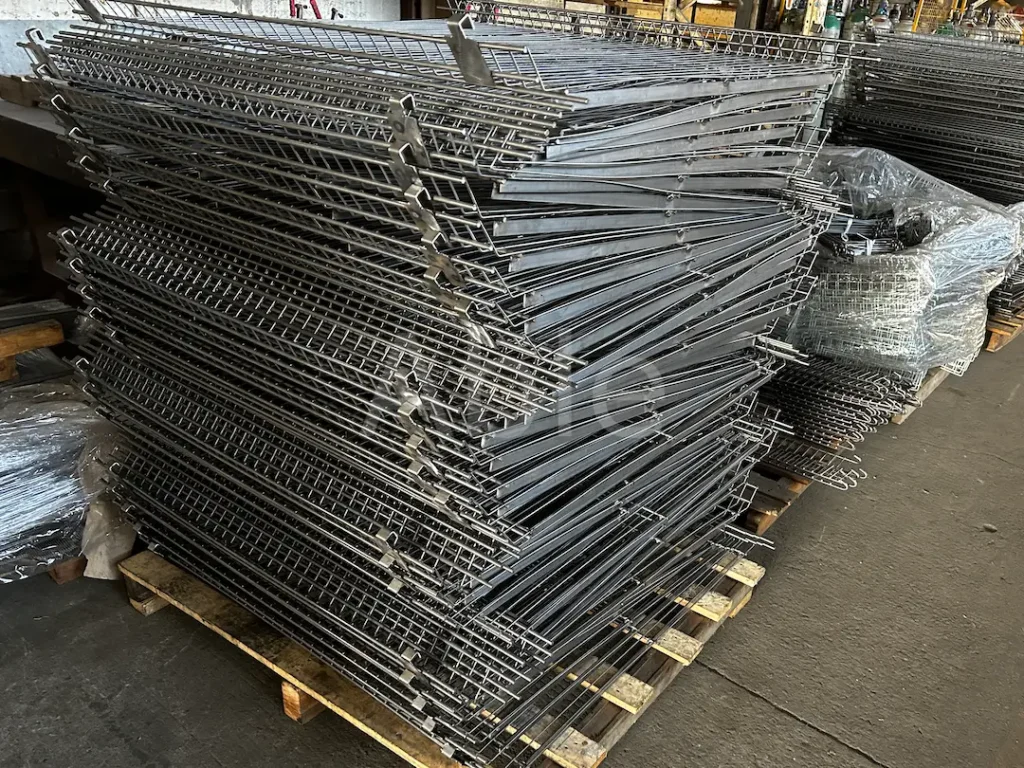

- Freezer baskets: stackable profiles, rolled rims, integrated handles; smooth edges for safe loading.

- Lüfterschutzgitter aus Draht: custom outer diameter, ring spacing, and blade-pitch compatibility; multi-point mounting plates.

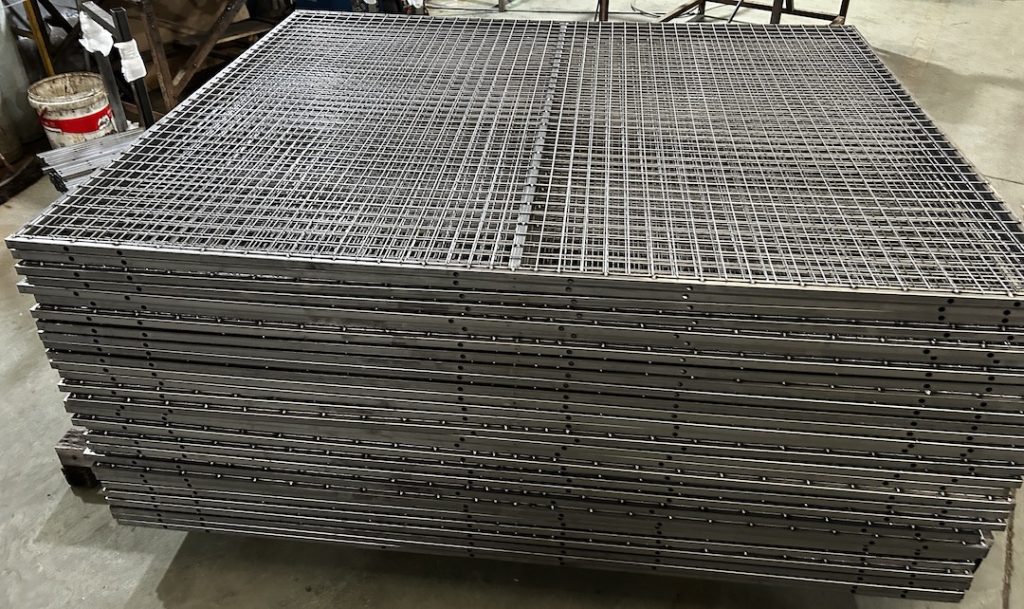

Retail/warehouse wire shelving & configurable accessories

- Modular shelves: optimized rib spacing for UDL targets; protective end caps and label features available.

- Accessories: Trennwände, hangers, product stops, and identification tabs built to drawing; coated for appearance and corrosion control. See the full category at Products → Wire.

Qualität & Testen

Was wir überprüfen (dimensional, finish tests, UDL checks) und Dokumentation

- Dimensional: wire diameter, Tonhöhe, overall L×W×H, Ebenheit, and bracket/plate locations.

- Load/UDL: sample shelf/basket deflection vs. Ziellast; pass/fail per agreed criteria.

- Beenden: Haftung (ASTM D3359), tragen (ASTM D4060), Korrosion (ISO 9227).

- Dokumentation: COA, Dimensionsberichte, Fai, PPAP (agreed list), material/finish traceability; optional CMM records.

Verpackung & Versand

KD/flat-pack, Beschriftung, ISPM-15 Paletten/Kisten; assembly guides

- KD/flat-pack wherever possible to minimize freight volume.

- Edge/paint protection with sleeves and guards.

- Barcode/labeling by SKU or kit; scan-ready carton IDs.

- Export pallets/crates zu ISPM-15 with moisture protection.

- Assembly guides and hardware kitting (Wenn angegeben). Learn more at Packaging & Versand.

Preisgestaltung & Vorlaufzeit

MOQ, Beispielrichtlinie, Indikative Kostenfahrer (Keine harten Preise)

- Lead-time model: prototype → tooling/fixture sign-off → SOP; Produktion über Abrufe/Pauschalaufträge.

- MOQ: aligned to coating line/electro-plating rack capacity and packing economics.

- Indicative cost drivers: Material (CRS vs. galvanized vs. 304/316), wire diameter and grid density, number of welds, added plates/handles, finish type and thickness, labeling/kitting, and export packing.

- Proben: off-tool samples prior to SOP; design tweaks can reduce cost and cycle time. Request a cost-down review via Laser Cutting & CNC Machining for hybrid plate-and-wire options.

Standards & Einhaltung

Relevante Standards/Zertifizierungen & Dokumentation bereitgestellt

- ISO 2768-m Allgemeine Toleranzen; ISO 9013 (thermal cut plate features).

- ASTM B633 Zinkbeschichtung; ASTM D3359 Haftung; ASTM D4060 tragen; ISO 9227 neutral salt spray.

- Delivery with COA, material/finish traceability, Dimensionsberichte, Fai, and PPAP basics (as agreed).

FAQ

What materials do you support?

Low-carbon steel, verzinkter Stahl, und rostfrei 304/316 upon request for demanding environments.

What wire diameters are typical?

Approximately 2.0–10.0 mm overall; shelves and baskets commonly use 3.0–6.0 mm primaries with smaller crosswires.

Which coatings are available?

Powder, vinyl/plastic dip, Zinkbeschichtung nach ASTM B633, and e-coat. Chrome is available only when specified.

How do you define load capacity?

We design to a UDL target set during DFM. Deflection and safety margin are validated on pre-production parts.

What tolerances do you work to?

General tolerances per ISO 2768-m unless specified. We follow your drawing for welded and plate features; CMM optional.

Welche QA-Dokumente können Sie bereitstellen??

COA, Dimensionsberichte, Fai, PPAP -Grundlagen, and traceability for materials and finishes.

Was ist die übliche Mindestbestellmenge und Vorlaufzeit??

MOQ depends on finish line setup and packing efficiency. Lead time follows prototype → tooling sign-off → SOP; schedules improve with blanket orders.

How are products packed for export?

KD/flat-pack with edge protection, barcode labeling, und ISPM-15 Paletten/Kisten. Assembly guides included when required.

What do you need for an RFQ?

2D/3D drawings, target UDL, material/finish, quantity tiers, testing/standards, Verpackung, und Lieferbedingungen.

Aufruf zum Handeln

Laden Sie Ihre Zeichnung hoch & get a quote today

Send drawings (STEP/DWG/PDF), target UDL and finish, quantity tiers, and packaging needs. We’ll return DFM notes, a quotation range, and a pilot schedule. Zeichnung hochladen / Holen Sie sich ein Angebot

Fordern Sie ein Angebot an

Mehr Kundenspezifische Drahtprodukte: