Inhaltsverzeichnis

Überblick & Anwendungsfälle

Why this solution for industrial environments

Able Hardware designs and manufactures welded frames and heavy-duty carts purpose-built for industrial equipment. Our approach combines automatic/robotic MIG welding for throughput and repeatability with CNC machining on critical datums to ensure precise mounting, smooth alignment, and reliable service life in harsh factory conditions. With structural carbon steels (Q235/S235, Q355/S355) as the baseline and optional 304/316 stainless or 6061/6082 aluminum for corrosion resistance or weight reduction, we deliver robust, export-ready assemblies at scale. Explore related capabilities: Benutzerdefinierte Metallrahmen, Schweißwagenwagen, automatisches Schweißen, Laserschnitt & CNC-Bearbeitung, Pulverbeschichtung.

Typical applications in industrial equipment

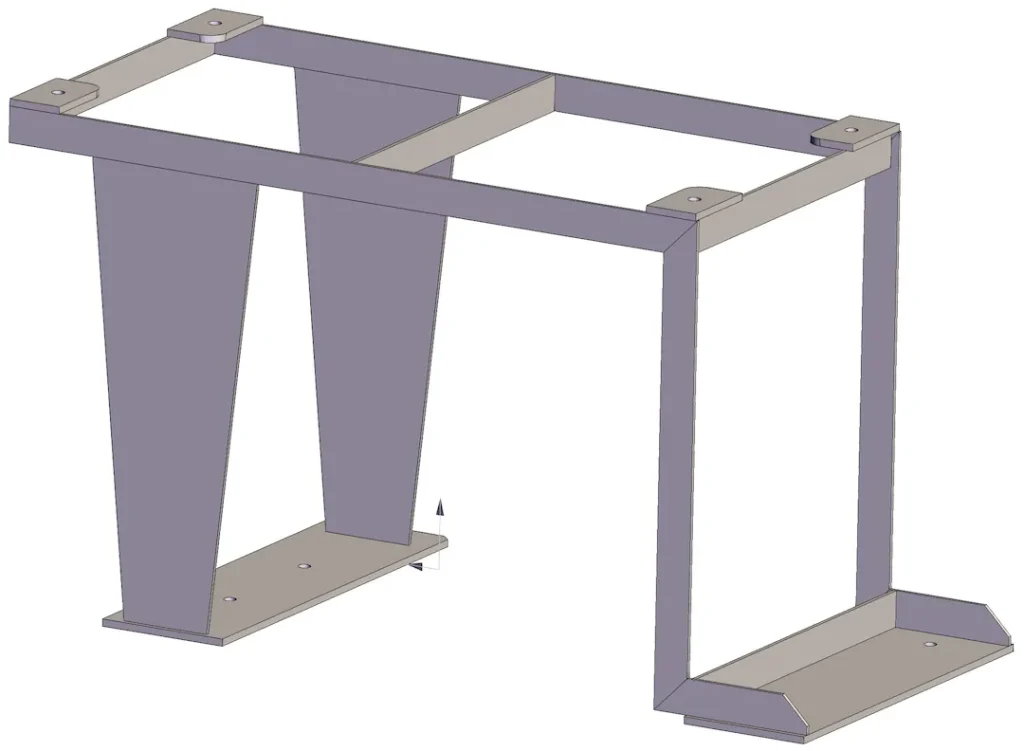

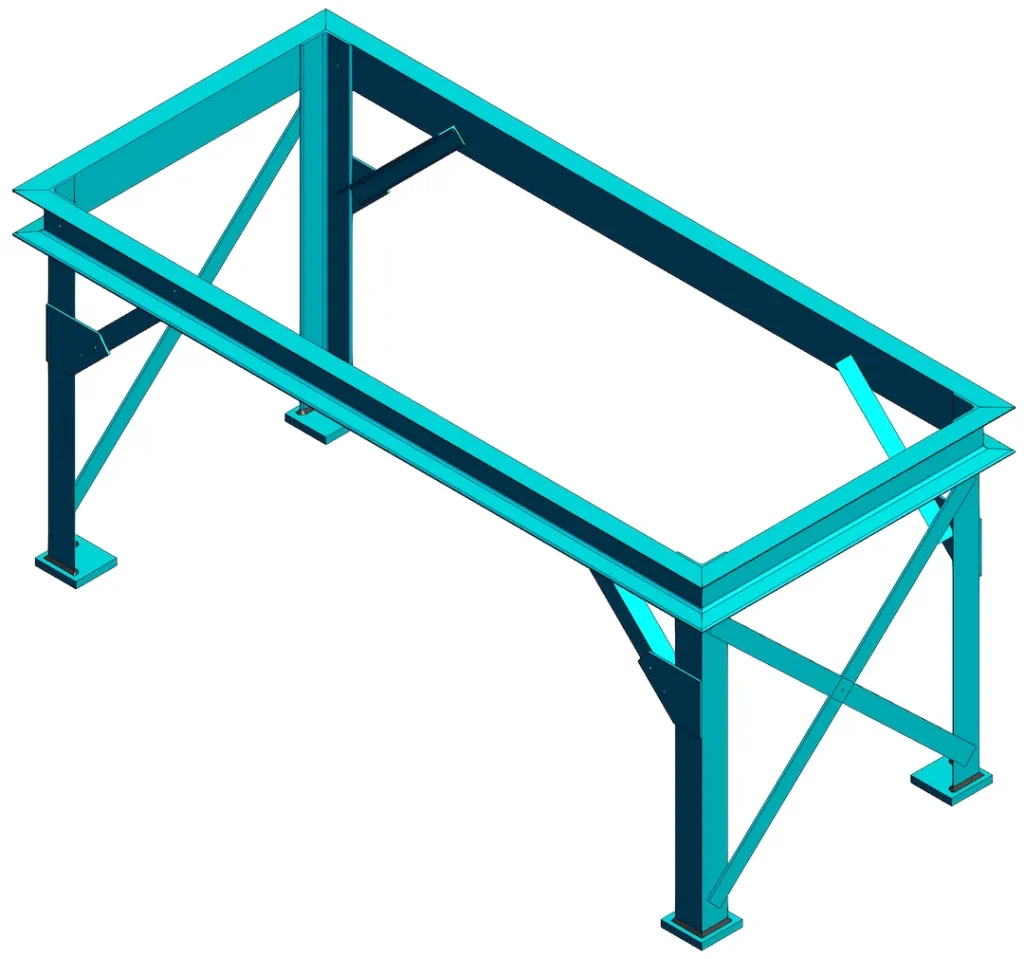

- Machine base and skid frames with milled datum pads, Ankerlöcher, Gabeltaschen, and leveling pads.

- Handling carts and tugger chassis for moving sub-assemblies between workstations; tuned for manual or tugged duty cycles.

- WIP racks and process fixtures with stiffness targets, shock/vibration considerations, and secure load restraint.

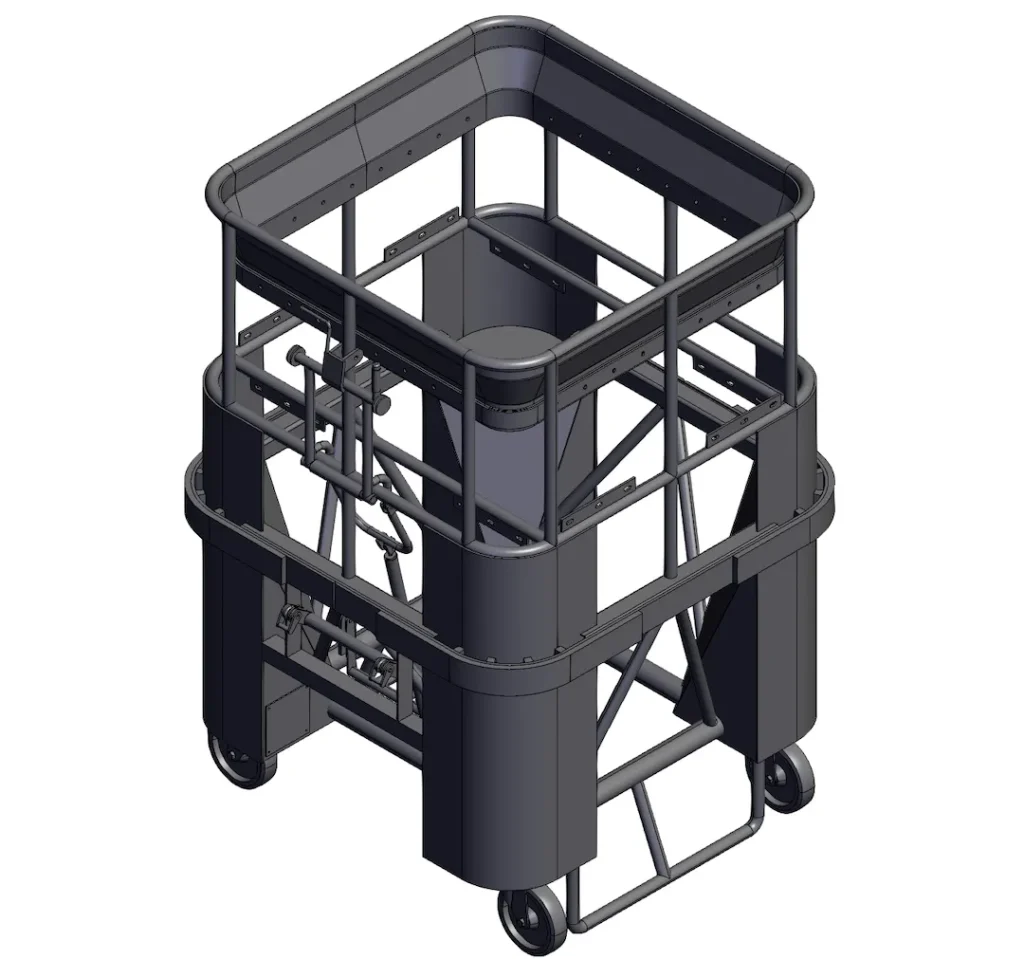

- Test/maintenance dollies with jack points, precision bores, and guarded casters for safe shop movement.

Technische Eigenschaften

Materialien, Profile & Lasten; Toleranzen (ISO 13920/ISO 2768) & Schweißqualität (ISO 5817)

- Materialien & Noten: Q235/S235 and Q355/S355 structural steels; optional 304/316 rostfrei; optional 6061/6082 Aluminium.

- Profile & Dicke: RHS/SHS, Winkel, Kanal, und Teller; tube and plate sections selected for stiffness-to-mass efficiency.

- Maße & Lasten: Typical L×W×H bands include 800×600×500 mm, 1000×800×750 mm, and 1200×1000×900 mm (custom sizes supported). Designed load capacities commonly 300–1,500 kg+ depending on geometry, section size, and caster rating. Duty cycles specified as manual push or tugged.

- Toleranzen: ISO 13920 class B/C guidance for welded constructions; ISO 2768 m/w für allgemeine Funktionen. For critical interfaces we target Flachheit ≤ 1,0–2,0 mm on datum pads and Quadratiness ≤ 1,5 mm/m, with holes and bores to drawing. Schweißsymbole nach ISO 2553.

- Schweißqualität: ISO 5817 Klasse c als Standard; Upgrade auf Klasse b on visible or safety-critical joints. Struktureller Bezug zu AWS D1.1 supplied if your specification requires it.

Oberflächen & Korrosionsschutz (ISO 12944/ISO 8501)

- Oberflächenvorbereitung: Abrasive blast and clean to ISO 8501 (z.B., Sa 2½) to prepare a consistent substrate.

- Coating systems: Powder coat to RAL with typical DFT 70–100 μm, zinc plating for hardware-heavy geometries, e-coat or industrial paint systems for complex layouts.

- Selection method: Coatings recommended using ISO 12944 by environment category (C2–C5) and durability target; DFT verified to ISO 2808. Where hygiene or chemical exposure is critical, 304/316 stainless or hybrid paint systems are considered.

Fertigungsoptionen

Automatische/Robotermig (und TIG, wenn angegeben), Vorrichtungen & Vorrichtungen, Wiederholbarkeit

Automatic/robotic MIG is our primary process for consistent bead profile, controlled heat input, and repeatable distortion management. TIG is available for stainless and cosmetic joints or thin-gauge features. We design custom jigs and fixtures to lock geometry, sequence welds for minimal warp, and hit takt. WPS/PQR are prepared when applicable, with trial coupons to validate parameter windows before serial build. Sehen automatisches Schweißen und engineering resources.

Sekundäre Ops: Laserschnitt, biegen, Bearbeitung; Beschichtung & Verpackung

Laser-cut blanks and formed components ensure tight fit-ups pre-weld. Post-weld CNC-Bearbeitung establishes precision datum pads, bearing bores, and alignment faces. Finishing includes powder coat, Zinkbeschichtung, E-Coat, or paint per ISO 12944. Export packaging uses Paletten/Kisten mit Schutzhülle, Eckwächter, and printed labels; a defined pcs per pallet plan improves unloading and line-side replenishment. Erkunden Laserschnitt & CNC-Bearbeitung und Pulverbeschichtung.

Typen & Geometrie

Common assemblies for industrial equipment (machine bases, skids, Karren, Gestelle) & Größenbänder

- Machine bases & skids: Boxed SHS/RHS skeletons with cross-members sized to stiffness targets; features include forklift pockets, Ankerlöcher, and milled leveling pads. Typical footprints from 800×600 to 1600×1200 mm; custom lengths for cell layouts.

- Handling carts & tuggers: Chassis designed for 300–1,000 kg loads, manuell oder gezogen. Frames integrate gusseted caster plates, Schleppstäbe, and lock-out hardware; optional AMR connection points.

- WIP racks & process frames: Modular uprights with locator pins, shock-isolating mounts, adjustable rails/shelves, and quick-release sub-frames for changeovers.

- Service/test dollies: Precision bores and jack points machined after weld; guards and bumpers to protect equipment and operators.

Qualität & Testen

Was wir überprüfen (Vt, DFT, Dimensionalprüfungen; Optionales PT/MT/RT) und Dokumentation (WPS/PQR, Kok)

- Inspection scope: 100% visual testing (Vt) of welds; dimensional checks per drawing, including CMM on datums and bores as needed. Beschichtung DFT checks to ISO 2808. Optional PT/MT/RT for critical welds or safety elements.

- Process control: Fixture verification, weld sequencing plans, and heat input windows to manage distortion on long spans.

- Dokumentation: WPS/PQR where applicable, material test data, finish certificates, full inspection reports, und Konformitätszertifikat (Kok) supplied with each lot. Acceptance criteria reference ISO 5817; geometry per ISO 13920/ISO 2768; weld symbols per ISO 2553.

Preisgestaltung & Vorlaufzeit

MOQ, Beispielrichtlinie, Indikative Kostenfahrer (Keine harten Preise)

Typisch MOQs are 50–100 pcs per model, depending on size and finish. Prototype samples can be produced within 7–15 working days after confirmed drawings; serial production commonly 25–45 days, influenced by fixture complexity, Bearbeitungsinhalte, und Beschichtungswarteschlange. Key cost drivers (guidance only):

- Section size and wall thickness; total weld length and requested weld class (ISO 5817 B vs c).

- Number of CNC-machined datums/bores and flatness requirements (≤1.0–2.0 mm).

- Coating system (Pulver, Zink, E-Coat, paint), target DFT, und ISO 12944 environment class.

- Caster grade, brake/tow hardware, und Zubehör.

- Packaging density (pcs per pallet) and export crate requirements. We provide target-cost feedback during DFM to balance stiffness, Gewicht, and finish against budget.

Standards & Einhaltung

Relevante Standards/Zertifizierungen & Dokumentation bereitgestellt

- Schweißen & Symbole: ISO 2553 (Schweißsymbole), ISO 5817 (weld quality classes), AWS D1.1 as structural reference if specified.

- Geometrie & Toleranzen: ISO 13920 (Schweißkonstruktionen), ISO 2768 m/f (allgemein).

- Oberfläche & Beschichtungen: ISO 8501 (Oberflächenvorbereitung), ISO 12944 (Korrosionsschutz), ISO 2808 (DFT). We mirror your drawing notes and include the required conformance documents with shipment.

FAQ

Q1. Which materials are most common for industrial bases and carts?

Q235/S235 and Q355/S355 are standard for strength and value; 304/316 stainless is chosen for corrosive or hygiene-critical areas; 6061/6082 aluminum is used where weight saving matters.

Q2. Can you hold tight datum and hole position tolerances on welded frames?

Ja. We machine datum pads and bores post-weld; typical guidance is pad flatness ≤1.0–2.0 mm and squareness ≤1.5 mm/m, with hole positions to drawing per ISO 13920/ISO 2768.

Q3. What weld class should I call out?

ISO 5817 Klasse c fits most internal joints; specify Klasse b for visible or critical joints. We can reference AWS D1.1 when requested.

Q4. How do you choose a coating system?

Based on ISO 12944 Umgebungskategorie (C2–C5) and durability target. Powder coat 70–100 μm is common; zinc plating or e-coat suit complex assemblies; stainless or hybrid paint used for demanding conditions.

Q5. What are typical MOQs and lead times?

MOQs generally 50–100 pcs; prototypes in 7–15 working days; production 25–45 days depending on fixtures, Bearbeitung, and coating capacity.

Q6. Can you support stainless cosmetic joints?

Ja. TIG is available for stainless or appearance-critical features; MIG remains primary for throughput and consistency.

Q7. What do you need to quote accurately?

2D/3D drawings with ISO 2553 Schweißsymbole, ISO 13920/ISO 2768 Toleranzen, target loads and duty cycle (manual/tugged), coating system and DFT, and packaging plan (Stück/Palette).

Zeichnung hochladen / Holen Sie sich ein Angebot

Ready to configure welded frames or carts for your line? Upload your drawings, Lasten, Toleranzen, beenden, and pcs/pallet plan. Wir werden das Feedback der Herstellbarkeitsfähigkeit zurückgeben, standard references, and a firm proposal with schedule and inspection scope.