Inhaltsverzeichnis

Überblick & Anwendungsfälle

Why this solution for retail environments

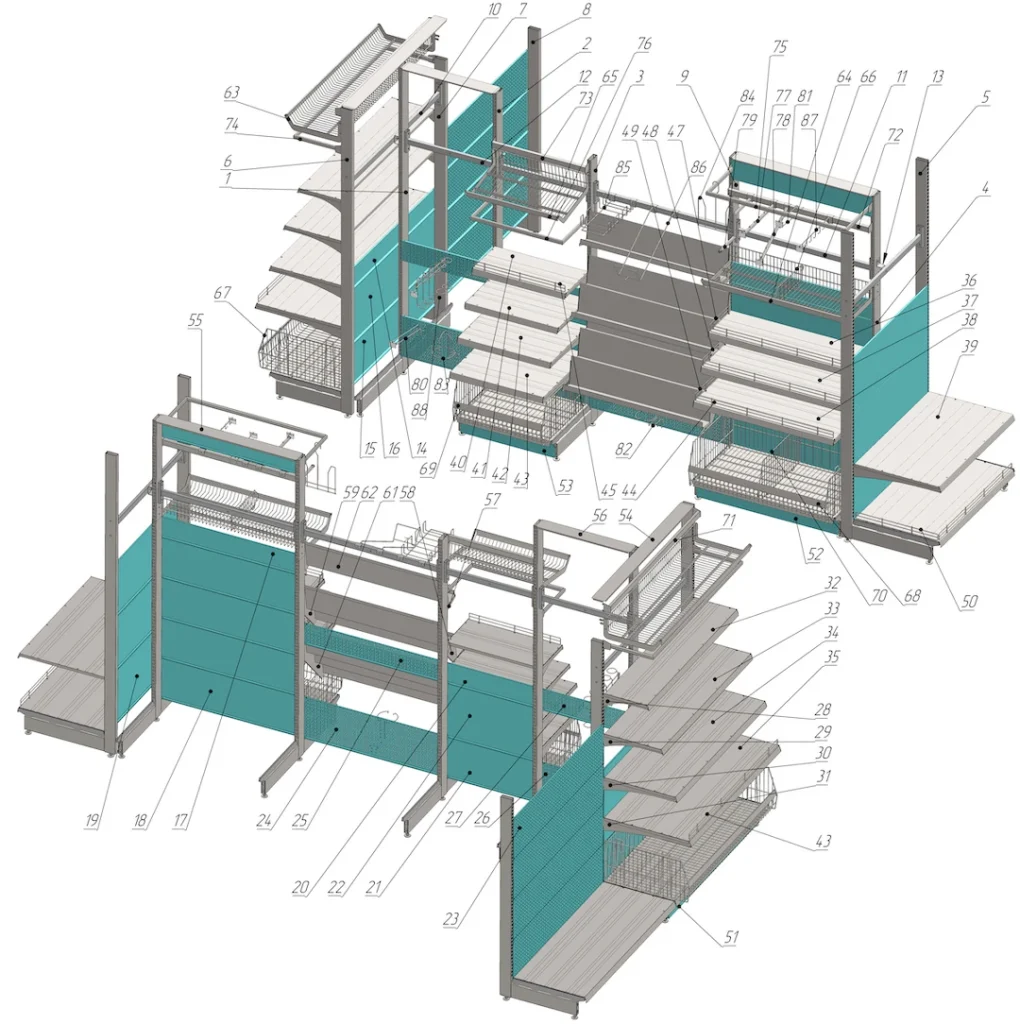

Able Hardware designs and builds fixture frames and wire displays that stand up to daily retail traffic while presenting a clean, premium look on the sales floor. We combine automatic/robotic MIG for carbon steel with TIG where cosmetic stainless welds matter, then finish with controlled powder coating for batch-to-batch color consistency across international rollouts. Kd (Knockdown) Konstruktion, concealed fasteners, and signage-friendly details speed installation and simplify planogram updates.

Typical applications in retail (Vorrichtungen, displays, rolling racks)

- Gondola bases/uprights, slotted panels, and shelf frames

- Wire shelves, Körbe, Trennwände, and peg/slatwall accessories with 25–50 mm grid pitch

- A-frames and nesting tables for seasonal/promotional displays

- Rolling racks with low-noise casters for apparel and back-of-house movement

- Signage holders, price rails, tablet stands, and color-matched accessories

Technische Eigenschaften

Materialien, Profile & Lasten; Toleranzen (ISO 13920/ISO 2768) & Schweißqualität (ISO 5817)

- Materialien & Noten: Q235/S235 and Q355/S355 carbon steel for strength and value; 304 rostfrei for hygiene and FOH cosmetics.

- Profile & Dicke: RHS/SHS/angle/tube/wire/plate. Typische Röhren 25×25×1.5 to 60×30×2 mm; Teller 2–8 mm; Draht Ø3–Ø8 mm. Grids in 25–50 mm pitch to meet loading and visibility needs.

- Maße & Lasten (typical bands):

- Gondolas: W 900–1200 × D 450–600 × H 1200–2100 mm, 10–80 kg per shelf depending on category.

- A-frames: W 1000–1600 × D 500–700 × H 1400–1800 mm.

- Nesting tables: L 900–1500 × W 600–900 × H 750–900 mm.

- Rolling racks: W 900–1500 × D 450–600 × H 1500–1800 mm; casters sized for manual rolling on tile/epoxy floors.

- Toleranzen: ISO 13920 Klasse B/c für Schweißkonstruktionen; ISO 2768-m/f for general dimensions. FOH geometry guidance includes panel flatness ≤1.0–2.0 mm und Quadratiness ≤ 1,5 mm/m. Deburr and cosmetic edge radii per drawing.

- Schweißqualität & Symbole: Visible joints to ISO 5817 Class B; hidden/structural joints to Class C. Symbols and callouts per ISO 2553.

Oberflächen & Korrosionsschutz (ISO 12944/ISO 8501)

- Pulvermantel: RAL-matched systems at 70–100 μm DFT with gloss, matt, or texture options; batch records held for rollout consistency.

- Rostfrei 304: Brushed/grain-matched; weld discoloration removed for FOH presentation.

- Hardware: Zinc/e-coat as specified.

- Oberflächenvorbereitung & Auswahl: Steel prepared per ISO 8501; coating systems chosen for indoor ISO 12944 C1–C3 environments (sales floor to BOH).

Fertigungsoptionen

Automatische/Robotermig (und TIG, wenn angegeben), Vorrichtungen & Vorrichtungen, Wiederholbarkeit

Robotic MIG cells standardize arc parameters and bead geometry on carbon steel frames, enabling stable takt times for high-volume programs. TIG is applied to 304 stainless or visible cosmetic joints. Custom jigs and datum pads control variation, während CNC-machined mounts enable fast, repeatable assembly in store or DCs.

Sekundäre Ops: Laserschnitt, biegen, Bearbeitung; Beschichtung & KD packaging

Laser schneiden produces price-rail windows, Schlüssel, and sign pockets; press-brake forming und Drahtbildung shape brackets and baskets; CNC-Bearbeitung tightens critical interfaces. Nach Abschluss, fixtures are KD-packed with barcoded labels, illustrated assembly sheets, protective wrap, and corner guards; pallet densities are optimized to reduce freight cost and damage.

Typen & Geometrie

Common assemblies for retail (Fixture -Rahmen, wire shelves/baskets, signage holders, rolling racks) & Größenbänder

- Fixture frames: Tube-and-plate bases with slotted or pegboard back panels; hole patterns aligned to 25 oder 50 mm increments for universal accessories.

- Wire shelves & Körbe: Primary wires Ø4–Ø6 mm with cross wires Ø3–Ø4 mm; edge hems or rod stiffeners to meet 10–80 kg per-shelf targets. Anti-snag wire ends specified for apparel and soft goods.

- Signage holders: Laser-cut frames (A5–A1), bolt-on or magnetic brackets; concealed fasteners to maintain brand aesthetics.

- Rolling racks: H- or Z-base frames with Zehenschutz, ergonomic handle height, and low-noise casters; optional ESD/grounding features for electronics retail.

Qualität & Testen

Was wir überprüfen (Vt, DFT, dimensional/AQL cosmetics; Optionales PT/MT/RT) und Dokumentation (WPS/PQR, Kok)

- 100% Vt of welds; dimensional checks to ISO 2768/13920 with optional CMM on datum features.

- Cosmetic AQL tailored to FOH visibility zones.

- Beschichtungen: DFT zu ISO 2808, adhesion/cure checks, and gloss/texture comparison against master chips.

- Functional tests: Wobble/tilt stability, push/pull force feel, caster roll with fastener torque verification, and tip-stability notes for tall fixtures.

- Dokumentation: WPS/PQR for robotic/TIG welds; Kok, Materialzertifikate, and inspection reports supplied per shipment.

Preisgestaltung & Vorlaufzeit

MOQ, pilot runs, Indikative Kostenfahrer (Keine harten Preise)

Wir unterstützen pilot runs for NPI and scale to wholesale rollout volumes. Indicative cost drivers include: Materialnote (Q235/S235 vs Q355/S355 vs 304/6061), tube/wire size, total weld length and cosmetic class (ISO 5817-B vs C), laser features, coating color changes/DFT, caster specification, and KD density (Stück/Palette). Lead time improves with consolidated colors, shared jigs, and repeat releases. Provide drawings and annual volume for a responsive VE (value-engineering) quote.

Standards & Einhaltung

Relevante Standards/Zertifizierungen & Dokumentation bereitgestellt

- Schweißen: ISO 5817 (Annahme), ISO 2553 (Symbole); AWS D1.1 used as reference if required by your standard library.

- Geometry/tolerances: ISO 13920 für Schweißkonstruktionen; ISO 2768-m/f for general features.

- Beschichtungen: ISO 8501 for prep; ISO 12944 for indoor corrosion categories C1–C3.

- Material/finish declarations: RoHS/REACH statements for coating systems and hardware available on request.

FAQ

What wire diameters and grid pitches are common?

Ø3–Ø8 mm wire with 25–50 mm Raster -Tonhöhe, tuned to shelf load and product size.

Can you hit ISO 5817-B on visible welds?

Yes—FOH joints are built/finished to Class B; non-visible joints default to Class C for cost control.

What tolerances should we call out?

Verwenden ISO 13920 B/c for welded frames and ISO 2768 m/f for general features; FOH targets include Flachheit ≤ 1,0–2,0 mm und Quadratiness ≤ 1,5 mm/m.

How do you manage RAL color consistency?

Pulvermantel 70–100 μm DFT with retained master chips and batch records. We supply witness panels for sign-off and align gloss/texture per spec.

Is KD packaging standard?

Ja-flat-pack with labeled fasteners, Barcodes, and assembly sheets; pallet counts planned to your DC standards.

What do you need for a quote?

Send STEP/DWG/PDF, Ziellasten (kg), RAL color/gloss/texture, signage/peg/slatwall requirements, and annual volume. We’ll respond with VE options and lead-time ranges.

Zeichnung hochladen / Holen Sie sich ein Angebot

Ready to refresh fixtures or launch a new display family? Upload your drawings and specs, note target loads, beenden (Ral + Glanz/Textur), KD packaging needs, and rollout volumes. Able Hardware will return a manufacturable proposal with coating samples and a pallet-efficient packing plan.