Descripción general & Casos de uso

Able Hardware diseña y fabrica bases de robots personalizadas, arrendador, pedestales, y marcos de celdas soldados que brindan estabilidad, plataformas precisas para robots industriales, cobots, y periféricos de automatización. Diseñado según especificaciones métricas con control de calidad listo para exportar, Nuestros ensamblajes combinan estructuras soldadas rígidas con almohadillas de referencia mecanizadas con precisión y patrones de anclaje para mantener su robot exactamente donde lo espera su programa, turno tras turno..

Tabla de contenido

Por qué esta solución para la robótica & entornos de automatización

La precisión de un robot es tan buena como la estructura que se encuentra debajo de él.. Nuestras soluciones de base y contrahuella soldadas aumentan la rigidez, elevar el alcance, y mejorar la línea de visión mientras controla la vibración y los efectos térmicos. Almohadillas niveladoras (M20-M30) y las cuñas de precisión permiten una instalación rápida; Las bandejas de cables y los pasos simplifican el enrutamiento.; Las almohadillas de referencia permiten la verificación CMM; y las interfaces de protección/cercas aceleran la integración de las células. Vea capacidades relacionadas en marcos metálicos personalizados, soldadura automática, y recubrimiento en polvo.

Aplicaciones típicas en células robóticas. (bases, arrendador, marcos de celdas)

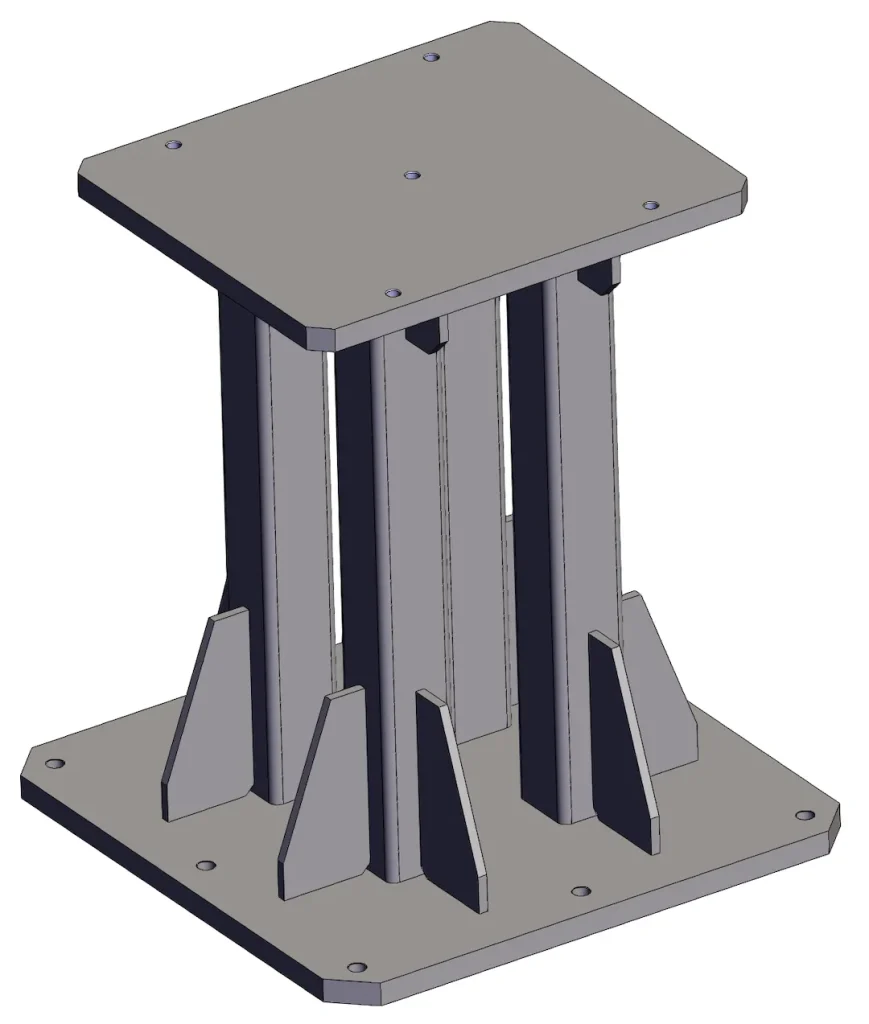

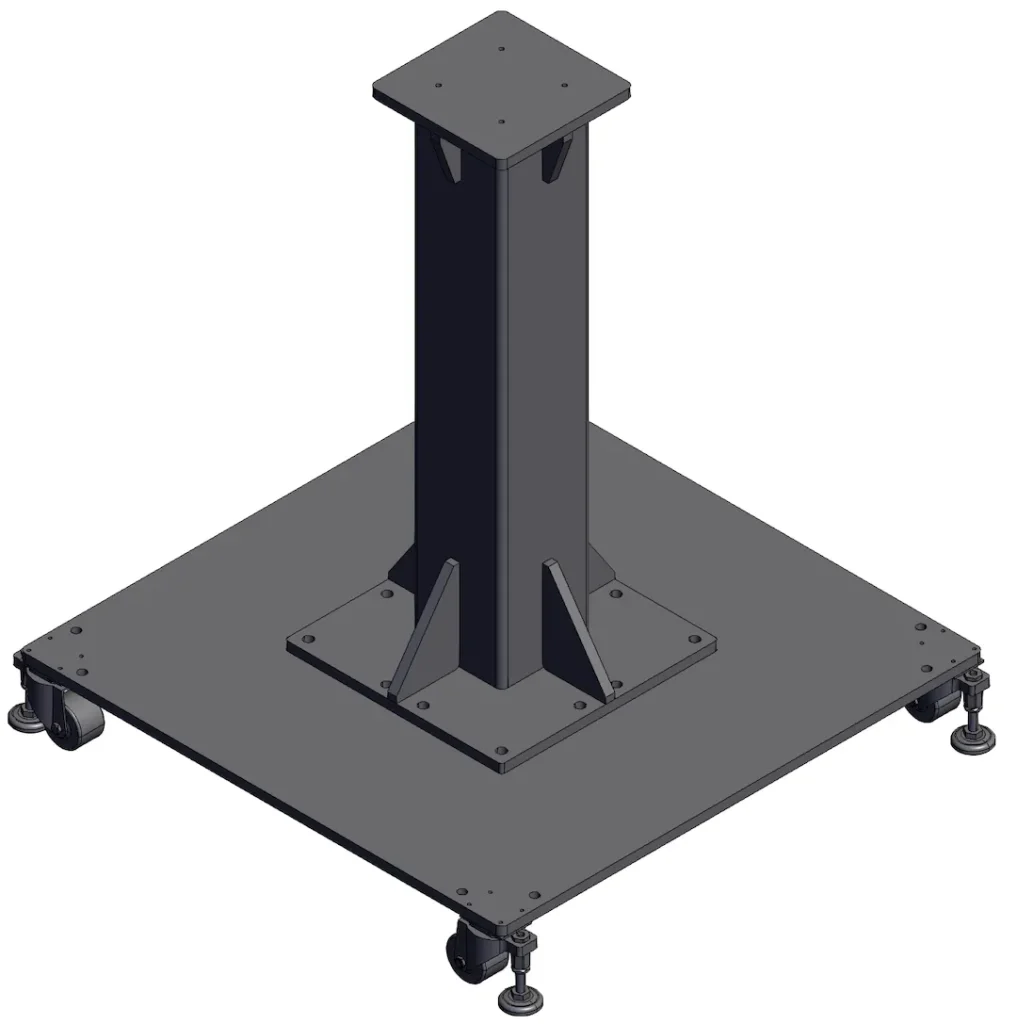

- Bases y elevadores de robot para establecer la altura/alcance para su manipulación, soldadura, paletizar, o inspección

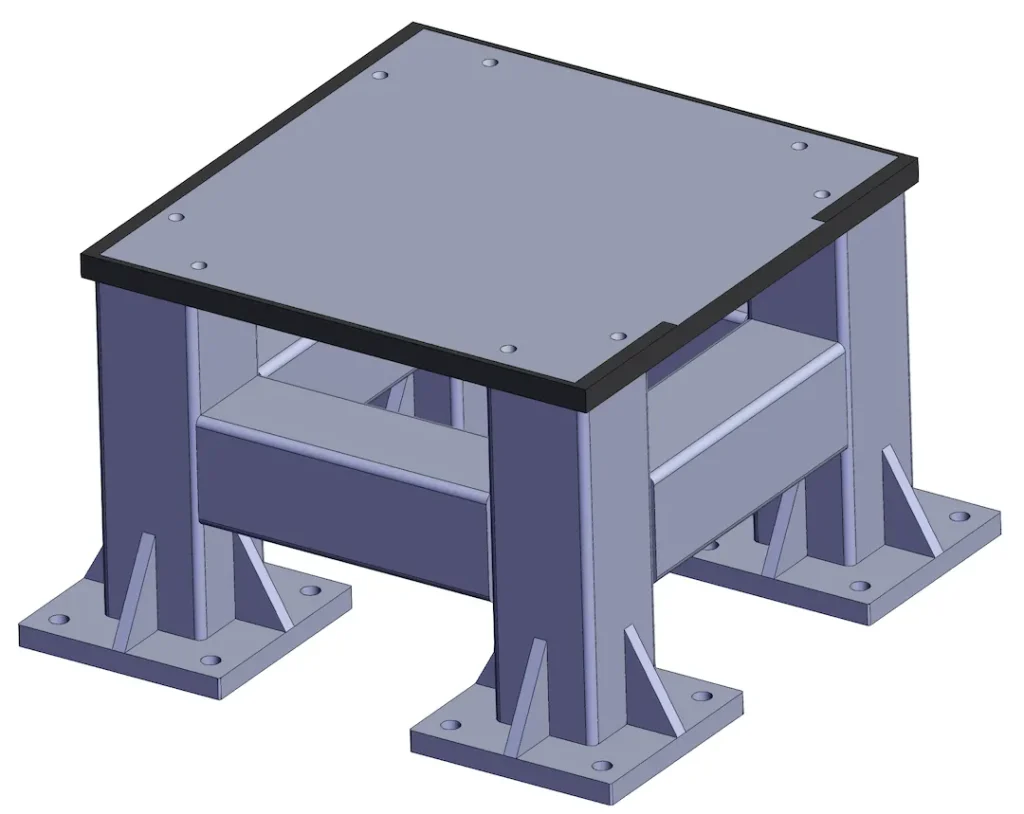

- Marcos celulares con gestión de cables integrada., rieles de servicios públicos, y proteger interfaces

- Pedestales con bolsas de lechada, placas de anclaje ranuradas, y puntos de unión enmascarados (ESD/tierra)

- Patines utilitarios para controladores, neumática, y distribución de energía debajo o al lado del robot

Propiedades técnicas

Materiales, perfiles & cargas; tolerancias (ISO 13920/ISO 2768) & calidad de soldadura (YO ASI 5817)

- Materiales & Los grados: Q235/S235 y Q355/S355 para una rigidez rentable; opcional 304/316 inoxidable para higiene/corrosión; opcional 6061/6082 aluminio para contrahuellas sensibles al peso.

- Perfiles & espesores: RHS/SHS, lámina, canal; tamaños de tubo típicos 40× 40 × 2 a 120 × 60 × 4 mm; placas base/superior 10–30 milímetros; buneses 6–10 milímetros.

- Dimensiones & cargas: Típico L×An×Al 600×600×200 a 2000×1500×1000 mm con cargas útiles adaptadas a su robot y herramientas de extremo del brazo. Coincidimos con el modelo de robot. huellas (milímetro) y patrones de anclaje (PCD/ranuras) según las especificaciones OEM.

- Tolerancias & control de geometría: YO ASI 13920 clase ANTES DE CRISTO para construcciones soldadas; YO ASI 2768 M/F general. Guía: planitud de la almohadilla ≤0,5–1,0 mm, paralelismo de las pastillas ≤0,5–1,0 mm, cuadratura ≤1,0–1,5 mm/m. Símbolos de soldadura por YO ASI 2553.

- Calidad de soldadura: YO ASI 5817 Clase B en juntas visibles/críticas; clase C en otra parte. Referencia estructural AWS D1.1 disponible bajo petición.

Acabados & protección contra la corrosión (ISO 12944/ISO 8501)

- Preparación de superficie: a YO ASI 8501.

- Recubrimientos: polvo (típico Ral, 70–100 μm), enchapado de zinc, e-carro, o pintura industrial seleccionada por ambiente utilizando YO ASI 12944 categorias.

- Eléctrico/ESD: Tierras enmascaradas y puntos de conexión proporcionados donde se especifica..

- Etiquetas & seguridad: etiquetas de activos, marcas de elevación/centro, y notas de torque/anclaje a pedido.

Opciones de fabricación

MIG automático/robótico (y tig si se especifica), plantillas & accesorios, repetibilidad

Usamos MIG automático/robótico para marcos de acero al carbono y Tig donde se especifican costuras inoxidables/cosméticas. Dedicado plantillas & accesorios Garantizar una cuadratura repetible y la ubicación del PCD de los orificios en todas las construcciones piloto y ejecuciones en serie.. WPS/PQR están disponibles cuando sea necesario.

Operaciones secundarias: corte con láser, doblando, mecanizado; gestión de cables, revestimiento & embalaje

- Corte por láser de placas base/superior, PCD, y anclajes ranurados; doblar/formar para refuerzos y características de bandeja.

- Mecanizado CNC de plataformas de referencia, aburre, y caras de interfaz para coplanaridad medida.

- Detalles de integración: bandejas de cables, ojales de paso, estantes del controlador, ojos levantados.

- Revestimiento a través de líneas internas/socios; embalaje con envoltura protectora, kits de pernos, cuñas, notas de montaje, y envíos en cajas/paletizados para exportación.

Tipos & Geometría

Conjuntos comunes para robótica. (bases de robots, arrendador, pedestales, marcos de celdas, patines de utilidad) & bandas de dimensionamiento

- bases de robots: marcos de perfil bajo con placas pesadas y almohadillas niveladoras; típico 600–1200 milímetros huellas cuadradas.

- Elevadores/pedestales: altura 200–1000 milímetros con refuerzos internos; Almohadilla superior mecanizada y perforada según modelo de robot..

- marcos de celda: subbases modulares para células multirobot, con interfaces de vigilancia y servicio.

- Patines de servicios públicos: RHS/estructuras de placa que soportan válvulas, fuerza, y refrigeración en un marco móvil o fijo. El tamaño depende de la huella del robot, cargas dinámicas, y estrategia de anclaje (PCD, rangos de ranuras, bolsas de lechada). Proporciona tu objetivo vibración/rigidez o inclinación/inclinación permitidas: nuestro soporte de ingeniería dimensionará las secciones en consecuencia.

Calidad & Pruebas

Lo que verificamos (Vermont, Dft, Comprobaciones de la MMC; PT/MT/RT opcional) y documentación (WPS/PQR, Coches)

- Inspección visual (Vermont 100%) de todas las soldaduras; YO ASI 2808 Dft controles del espesor del recubrimiento.

- MMC verificación de PCD, almohadillas de referencia, y coplanaridad/paralelismo de la plataforma; documentado ras cheques.

- NDT opcional: PT/MT/RT para juntas críticas según su plan.

- Documentos entregados: WPS/PQR (si es aplicable), Coches, certificados de materiales, e informes de inspección.

Precios & Tiempo de espera

Moq, compilaciones de muestra/piloto, conductores de costos indicativos (Sin precios duros)

- Moq: flexible para prototipos/pilotos; Las series económicas comienzan con pocas docenas dependiendo del tamaño..

- Tiempo de entrega: prototipos típicamente 2–4 semanas después del cierre del sorteo; producción 4–7 semanas dependiendo de la cola de recubrimiento y el contenido de mecanizado.

- Impulsores de costos: espesor y grado de la placa, mecanizado de almohadillas/agujeros de referencia, sistema de recubrimiento (polvo vs e-coat), clase de tolerancia (YO ASI 13920 B contra C), alcance de END, y kit de embalaje/exportación. Proporcione dibujos con planitud/paralelismo objetivo y modelo de robot/PCD para refinar la cotización..

Estándares & Cumplimiento

Normas/certificaciones relevantes & documentación proporcionada

Construimos para YO ASI 13920, YO ASI 2768, y YO ASI 2553 simbolizando, con aceptación de soldadura para YO ASI 5817 (Clase B/C). Los recubrimientos se seleccionan y verifican para YO ASI 12944 con preparación para YO ASI 8501. A solicitud, los proyectos pueden hacer referencia AWS D1.1 para orientación estructural e incorporar WPS/PQR y calificaciones de soldador en consecuencia.

Preguntas más frecuentes

Q1. Que materiales me recomiendas?

Aceros al carbono Q235/S235 o Q355/S355 ofrecer la mejor relación rigidez-precio. Elegir 304/316 inoxidable para higiene/exposición a la corrosión, o 6061/6082 aluminio para contrahuellas sensibles al peso.

Q2. ¿Qué objetivos de rigidez/nivelación son típicos??

La guía común es planitud de la almohadilla ≤0,5–1,0 mm y paralelismo ≤0,5–1,0 mm a través de almohadillas de montaje, con general cuadratura ≤1,0–1,5 mm/m. Dimensionaremos las secciones para cumplir con sus límites de deflexión..

Q3. ¿Qué tan ajustadas se pueden mantener las tolerancias de PCD y de referencia??

Los orificios cortados con láser y los puntos de referencia mecanizados por CNC logran de forma rutinaria ±0,1–0,2 mm Ubicación en PCD según el tamaño.; verificamos con MMC y proporcionar informes.

Q4. ¿Qué clase de soldadura usas??

juntas visibles/críticas para YO ASI 5817 Clase B, juntas generales del marco para clase C, a menos que su especificación requiera lo contrario.

Q5. ¿Qué recubrimientos y bases enmascaradas pueden proporcionar??

Polvo (tipo. 70–100 μm), enchapado de zinc, e-carro, o pintar. nosotros enmascaramos puesta a tierra/ESD puntos por dibujo y puede agregar etiquetas para unir.

Q6. ¿Cuáles son los MOQ y el tiempo de entrega??

Bienvenidos prototipos; La cantidad mínima de pedido de la serie depende del tamaño y el revestimiento.. Plazos de entrega típicos: 2–4 semanas (prototipo), 4–7 semanas (serie).

Q7. ¿Qué dibujos necesitas para cotizar??

Proporcionar L×An×Al, robot huella y PCD, tolerancias objetivo (planitud/paralelismo), sistema de recubrimiento, y documentos NDT/QA requeridos.

Subir dibujo / Obtener una cotización

Listo para dimensionar su base o contrahuella? Sube tu dibujo (PASO/DWG/PDF) con modelo de robot, PCD, y objetivos de tolerancia. Nuestro equipo de ingeniería propondrá una solución rentable, diseño comprobable y emitir un rápido servicio personalizado cotización.