Aperçu & Cas d'utilisation

Fourniture de matériel capable Fabrication de métaux personnalisés avec soudage automatique / robotique et usinage CNC Pour les acheteurs OEM / ODM qui ont besoin d'une qualité reproductible à grande échelle. Nous nous construisons pour traverser les soudeurs cadres en acier, chariots de chariot / utilitaire, et produits de fil (rayonnage, paniers, gardes), puis terminer et emballer pour l'exportation. Les enveloppes de construction typiques vont de 400× 300 × 200 mm jusqu'à 2000× 1200 × 900 mm; La capacité de charge est conçue par profil, épaisseur de paroi, et conception conjointe. Explorez notre capacité de soudage.

Pourquoi cette solution pour les environnements exigeants

Le soudage automatique fournit Géométrie de perles cohérente, variabilité plus faible, et haut takt, Le rendre idéal pour les bases d'équipement, cingt 24/7 manipulation des matériaux, et ensembles de fil rigide. Avec des matériaux ajustés, classe de soudure, et revêtement (par ISO 12944), Vos assemblages résistent aux vibrations, impact, et l'altération tout en maintenant l'alignement.

Industries typiques & applications

- Équipement industriel & machinerie: Cadres de base de la machine / du dérapage, garde, sous-cadres

- Robotique & automation: bases de robot, curseurs, cellules, cadres de luminaire

- Entrepôt & logistique: camions de plate-forme, chariots de sélection de commandes, étagères à fil et supports

- CVC / électrique: cadres de support, Pays de câbles / gardes, enclos

- Automobile & agricole: séances d'essai, chariots utilitaires durables, paniers en fil

Sélectionnez simplement les critères pour vous ci-dessous et vous serez redirigé vers la catégorie appropriée.

Propriétés techniques

Matériaux & profils; tolérances (ISO 13920 / ISO 2768) & qualité de soudure (ISO 5817)

- Matériaux & notes: Q235 / S235 Pour les structures générales; Q355 / S355 pour une rigidité et une charge plus élevées; 304/316 inoxydable où la corrosion / l'hygiène est critique; 6061/6082 aluminium Disponible lorsque le léger est requis.

- Profils & épaisseur: RHS / SHS, Angle, Canal, Plaque - tubes typiques 40× 40 × 2 à 120 × 60 × 4 mm; assiette 4–20 mm. Produits en fil Spécifiez couramment fil Ø en mm avec des traitements de hauteur de grille et de bord par dessin.

- Tolérances: Constructions soudées à ISO 13920 classe B / C; Caractéristiques générales de ISO 2768 m / f. Cibles de guidage avec correction / séquençage correct: planéité ≤1,0–2,0 mm, Connexion ≤ 1,5 mm / m. Symboles de soudure par ISO 2553.

- Qualité de soudure: ISO 5817 Classe C standard; classe B sur les articulations critiques / visibles. Les critères structurels peuvent faire référence AWS D1.1 Lorsqu'il est spécifié.

Finitions & protection contre la corrosion (ISO 12944 / ISO 8501)

- Manteau en poudre (Ral) 70–100 μm, placage de zinc, coat électronique, ou peinture industrielle.

- Préparation de surface par ISO 8501 (par exemple., À 2½ explosions); Sélection du système par ISO 12944 catégories d'environnement. Masquage disponible pour les terrains / coussinets de données; revêtement Dft vérifié par ISO 2808.

Options de fabrication

Mig automatique / robotique (et tig si spécifié), gabarits & luminaires, répétabilité

- Mig automatique / robotique est notre valeur par défaut pour l'acier au carbone - arc stable, éclaboussures, et répétabilité de lot à lot.

- TIG Appliqué pour les joints en acier inoxydable ou visibles nécessitant des cosmétiques élevés et une entrée de chaleur contrôlée.

- Gabarits personnalisés & luminaires Conçu sur votre schéma de référence; Les séquences de soudure documentées limitent la distorsion et assurent une géométrie cohérente. En savoir plus sur Soudage automatique .

OPS secondaires: coupure laser, pliant, usinage; revêtement & emballage

- Découpe au laser & Usinage CNC: blancs, trous à fente, inserts taraudés, Datums fraisés, contre-bases.

- Fense / formation: supports, goussets, canaux; formage de fil Pour les étagères / paniers par pit et rayon de bord.

- Revêtement: interne manteau en poudre ou partenaire zinc / e-coat / peinture. En savoir plus sur traitement de surface.

- Emballage d'exportation: palette ou caisse avec enveloppe protectrice, gardes d'angle, et étiquettes; typique 4–8 PC / palette en fonction de la taille et de la protection de la finition.

Types & Géométrie

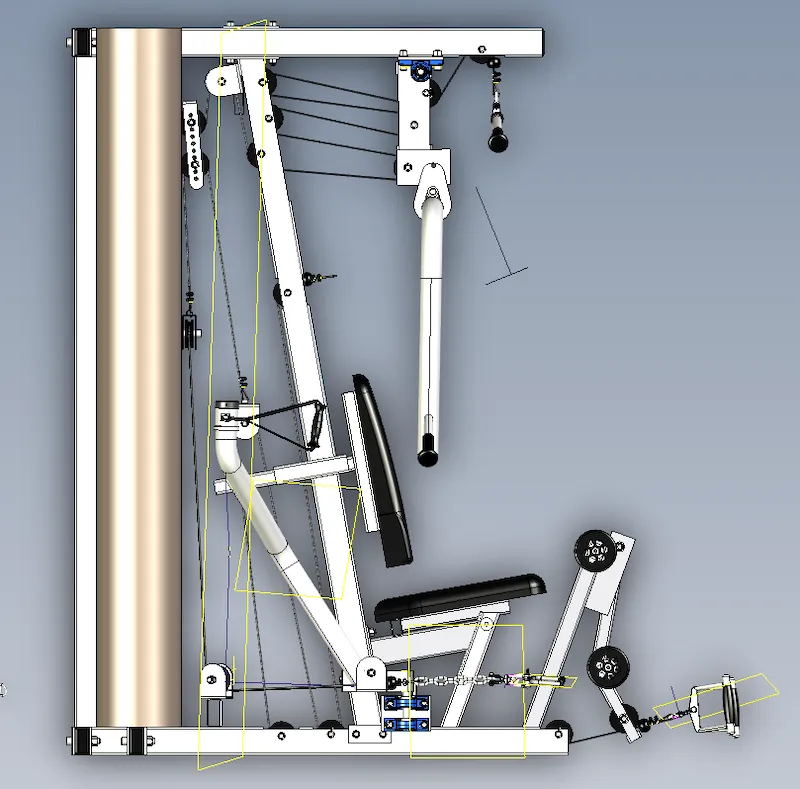

Formes communes (Cadres de base de la machine / du dérapage, Cadres de boîte / tube, chariots de chariot / utilitaire) & bandes de dimensionnement

- Base de la machine & cadres de dérapage: RHS / assiette lourde; coussinets de nivellement; faces de réduction usinées; typique 800× 600 × 500 à 2000 × 1200 × 900 mm.

- Cadres d'équipement de boîte / tube: Structures SHS / RHS avec plaques de montage, supports pour panneaux / capteurs / plateaux de câble.

- Chariots de chariot / utilitaire: camions de plate-forme, chariots de sélection de commandes, chariots de service en acier inoxydable, Dolons à profil bas; Packages de lanceurs roue Ø, Matériel, palier, et chargement / lanceur.

- Produits en fil: rayonnage, paniers, gardes, grilles filaires soudées avec spécifiée fil Ø, pas, Retour des bords, et onglets de montage. Tous les projets sont au dessin (Pdf / dwg / étape); Nous pouvons recommander des ensembles de profil, Cours de soudure, paquets de lancers, et des spécifications de fil pour atteindre les cibles de charge et de tolérance. Voir les atterrissages du produit à /products/custom-metal-frames/ et /products/welding-trolley-carts/.

Qualité & Essai

Ce que nous vérifions (Vermont, Dft, chèques dimensionnels; PT / MT / RT en option) et documentation (WPS / PQR, Coc)

- Inspection visuelle (Vermont) 100% par ISO 5817 niveaux d'acceptation (continuité, saper, chevaucher, Élimination des éclaboussures).

- Vérification dimensionnelle Pour dessiner GD&T et ISO 13920 / ISO 2768; Vérification CMM / Gauche sur les données critiques et les plans de montage.

- Revêtement QC: Dft par ISO 2808, Match de couleurs RAL; Tests d'adhésion sur demande.

- NDT en option: PT / MT / RT pour les soudures critiques comme spécifié.

- Documentation: WPS / PQR (Lorsqu'il est contracté), rapports d'inspection, Certificat de conformité, Listes d'emballage avec traçabilité.

Prix & Délai de mise en œuvre

MOQ, Exemple de politique, Conducteurs de coûts indicatifs (Pas de prix difficiles)

- MOQ dépend de la taille, Investissement de luminaire, Tire / outillage, complexité du package de lanceur, et la taille du lot de revêtement; Buillés pilotes disponibles pour l'ajustement et la fonction.

- Délai de mise en œuvre varie en dessinant la complexité, classe de soudure, Fidoirs d'usinage et de revêtement, et Logistic Lane.

- Primaires de coûts principaux: grade de matériel & épaisseur, longueur de soudure & ISO 5817 classer, Nombre de fonctionnalités d'usinage, fil Ø et pas de grille, système de revêtement (Changements RAL), méthode d'emballage, et mode d'expédition. Fournir un volume annuel et une cadence de libération pour optimiser l'amortissement des luminaires.

Normes & Conformité

Normes / certifications pertinentes & documentation fournie (AWS D1.1, ISO 5817, ISO 2553, ISO 13920, ISO 2768, ISO 12944, ISO 8501)

Nous construisons votre spécification et nous alignons avec:

- AWS D1.1 (référence en acier structurel)

- ISO 5817 (Niveaux de qualité de soudure b / c / d)

- ISO 2553 (Symboles de soudage)

- ISO 13920 (Tolérances pour les constructions soudées)

- ISO 2768 (tolérances générales)

- ISO 12944 / ISO 8501 (systèmes de revêtement & Préparation de la surface)

FAQ

Q1: Quels matériaux soutenez-vous pour les cadres, chariots, et les produits en fil?

Q235 / S235 et Q355 / S355 Les aciers en carbone sont standard; Nous fabriquons également dans 304/316 inoxydable pour la corrosion ou l'hygiène et 6061/6082 aluminium Quand le poids compte.

Q2: Quelle qualité de soudure et des tolérances pouvez-vous rencontrer?

Soudure à ISO 5817 Classe C (ou B pour les articulations critiques / visibles). Dimensions par ISO 13920 B / c et ISO 2768 m / f; Avec un correctif approprié, nous cibler planéité ≤1,0–2,0 mm et Connexion ≤ 1,5 mm / m où la conception permet.

Q3: Pouvez-vous des faces de montage de machine et intégrer des inserts filetés?

Oui - coupe laser et Usinage CNC Ajouter des emplacements, trous taraudés, contre-bases, et des coussinets de rétesses de réduction pour assurer l'assemblage de rendez-vous.

Q4: Fournissez-vous des roues et finissez-vous pour les chariots?

Oui - les packages de tests sont dimensionnés par roue Ø / matériau / roulement / charge; Les finitions incluent manteau en poudre (70–100 μm), zinc, coat électronique, ou peinture industrielle.

Q5: Comment pouvons-nous accélérer la citation?

Partager Pdf / dwg / étape, grade de matériel, tailles de tube / fil, classe de soudure (ISO 5817), cibles de tolérance (ISO 13920/2768), finition (Ral), quantité, destination, et toutes les exigences NDT / QA.

Q6: Quel emballage utilisez-vous pour l'exportation?

Palettes ou caisses avec enveloppe et étiquettes protectrices; typique 4–8 PC / palette, Optimisé pour le chargement des conteneurs et la protection de la finition.

Q7: Construisez-vous des gabarits / luminaires pour les commandes répétées?

Oui-gabarits personnalisés & luminaires Assurer la répétabilité et réduire le coût unitaire entre les versions prévues.

Appel à l'action

Prêt à construire votre prochain ensemble soudé ou produit métallique? Téléchargez des dessins et des exigences pour recevoir un devis et un délai rapide. Obtenez un devis → Attacher pdf / dwg / étape; inclure les tolérances cibles, Tailles de fil ou de tube, et finir (Ral).