Table des matières

Matériel capable est un OEM/ODM basé en Chine usine livraison de patins soudés, cadres de plancher, et chariots de kitting/train de remorquage conçus pour les environnements automobiles et agricoles à forte utilisation. Nous combinons MIG automatique/robotique soudage (avec TIG lorsque des coutures inoxydables ou cosmétiques sont nécessaires), découpe laser en amont, usinage de précision, et une assurance qualité prête à l'exportation pour fournir des assemblages reproductibles qui s'intègrent dans vos exigences logistiques côté ligne et PPAP.

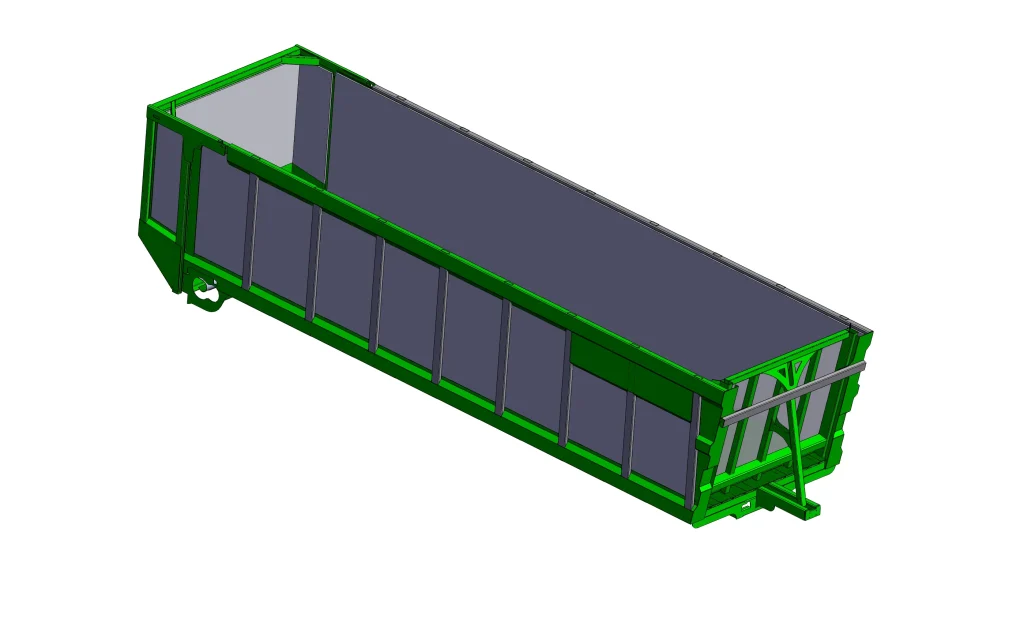

Aperçu & Cas d'utilisation

Pourquoi cette solution pour l'automobile & milieux agricoles

Les modules de production et les pièces de rechange transitent par des installations qui imposent choc, vibration, et takt serré. Nos bases et chariots soudés sont conçus autour de ces réalités: aciers de construction (Q235 / S235 et Q355 / S355) assurer rigidité et durabilité; Datums fraisés et les PCD usinés garantissent une localisation précise; barres de remorquage, récepteurs à broches, trous d'ancrage, et passages pour chariots élévateurs s'intégrer aux équipements de manutention existants. Là où des nettoyants hygiéniques ou agressifs s’appliquent (par exemple., lavage du groupe motopropulseur), nous offrons 304/316 inoxydable; pour une force de poussée et une consommation d'énergie réduites, 6061/6082 aluminium réduit la masse sur les chariots et les accessoires de kitting.

Applications typiques côté ligne, kitting, et opérations de service

- Patins moteur/boîte de vitesses & berceaux avec tampons de référence usinés pour la répétabilité du localisateur.

- Carrosserie/cabine/cadres d'essieu dimensionné pour les modules communs (L×L×H de 800×600×500 mm à 2000× 1200 × 900 mm).

- Séquençage & chariots de kitting pour garniture, électrique, et attaches, avec ESD/patins de mise à la terre quand l'électronique est présente.

- Chariots de remorquage pour les courses de lait (service manuel/remorqué/train), charges utiles 200–1500 kg.

- Cadres de service sur le terrain avec pare-chocs de protection et attaches.

Propriétés techniques

Matériaux, profils & charges; tolérances (ISO 13920 / ISO 2768) & qualité de soudure (ISO 5817)

- Matériaux & notes: Q235 / S235, Q355 / S355; facultatif 304/316 inoxydable et 6061/6082 aluminium.

- Profils & épaisseur: RHS/SHS/angle/canal/plaque; tubes de 40×40×2 à 120×60×4 mm; assiette 4–20 mm.

- Charge/devoir: Conçu pour le manuel, tiré, ou service de train; dimensionnement des éléments et soufflets adaptés à la charge utile et au centre de gravité.

- Tolérances: Constructions soudées à ISO 13920 classe B / C; tolérances générales ISO 2768 m / f. Conseils: planéité ≤1,0–2,0 mm sur les blocs de référence; Connexion ≤ 1,5 mm / m. Symboles de soudure par ISO 2553.

- Qualité de soudure: Défaut ISO 5817 Classe C; classe B pour les joints visibles ou critiques pour la sécurité. Référence structurelle à AWS D1.1 si demandé.

Finitions & protection contre la corrosion (e-coat/zinc/poudre selon ISO 12944/ISO 8501)

- Préparation de surface: Nettoyer/sabler ISO 8501; références de masque et alésages de roulements.

- Systèmes: Manteau électronique pour couvrir les cavités; placage de zinc pour une protection sacrificielle; manteau en poudre (Ral, 70–100 μm DFT) pour une couleur durable; peinture industrielle sur demande.

- Options recto-verso: Zinc + poudre ou coat électronique + poudre pour environnements sévères.

- Vérification: TFD par ISO 2808; sélection par catégorie d'environnement pour ISO 12944.

Options de fabrication

Mig automatique / robotique (et tig si spécifié), gabarits & luminaires, répétabilité

- Mig automatique / robotique fournit des congés et un temps de cycle cohérents; TIG utilisé sur des sections inoxydables ou minces nécessitant un contrôle cosmétique. Explorer en relation Soudage robotisé automatisé.

- Gabarits personnalisés & luminaires fournir des arrêts durs et une stratégie de serrage pour la répétabilité; accès conçu pour le chemin de la torche et le contrôle des projections.

OPS secondaires: coupure laser, pliant, usinage; revêtement & emballage

- Découpe au laser, pliage/formage pour tube et plaque; Usinage CNC pour le rendez-vous, alésages, et PCD; inserts, bagues, et fonctionnalités threadées installées comme spécifié.

- Revêtement intégré à vos spécifications; emballage en palette/caisse avec film de protection et étiquettes; fardage consigné hébergé; pcs par palette définie lors de l'APQP. Voir: /services/laser-cutting-cnc-machining/ · /services/powder-coating/

Types & Géométrie

Assemblages courants pour l'automobile & agricole

- Patins soudés & cadres de plancher: Bases RHS/SHS avec traverses; membres principaux typiques 60×40×3 ou 80×40×3 mm; passages pour chariots élévateurs, pattes de levage, trous d'ancrage.

- Cadres/fixations de modules: Berceaux imbriqués avec Datums fraisés; la pile de tolérance a réussi à ISO 13920 B sur les plots de localisation.

- Chariots de kitting/remorqueurs:

- Roulettes: PU, nylon, fonte, ou du caoutchouc; Ø125/150/200mm; roulements à billes ou à rouleaux.

- Mises en page: 2 rigide + 2 pivot ou 4 pivot avec freins ou verrouillage centralisé.

- Charger les mathématiques: Supposer 3 de 4 les roulettes supportent la charge lorsqu'elles tournent; appliquer 1.3–2,0 facteur de sécurité. Exemple: 1000 kg charge utile ⇒ 1000/3 ≈ 333 kg par roulette × 1.5 SF ⇒ choisir ≥500kg roulettes évaluées (Ø150–200 mm selon le sol).

Qualité & Essai

Ce que nous vérifions (Vermont, Dft, chèques dimensionnels; PT / MT / RT en option) et documentation (Éléments PPAP sur demande, WPS / PQR, Coc)

- 100% Vermont sur les soudures; chèques dimensionnels sur les données clés et l'encombrement; Cmm pour PCD et tampons de précision si nécessaire.

- Assurance qualité du revêtement: Contrôles TFD par ISO 2808; adhésion/durcissement selon les spécifications.

- NDT en option: PT / MT / RT sur les articulations critiques.

- Documentation: WPS / PQR, Coc, rapports d'inspection; Éléments PPAP (Fai, Plan de contrôle, PFMEA, MSA, PSSP) à la portée convenue. En savoir plus sur la qualité des soudures: /standards/iso-5817/. Explorez les Document d'assurance qualité.

Prix & Délai de mise en œuvre

MOQ, Exemple de politique, Conducteurs de coûts indicatifs (Pas de prix difficiles)

- MOQ: Aligné sur la taille du lot, couleur du revêtement, et plan de fardage; prototypes/échantillons disponibles.

- Délai de mise en œuvre: Prototypes en semaines; l'approvisionnement en série dépend de la construction du gabarit, contenu d'usinage, et file d'attente de revêtement.

- Facteurs de coûts: Nuance/épaisseur d'acier; longueur totale de soudure et niveau de qualité (C contre B); références usinées/PCD; type de roulette/diamètre/quantité; revêtement duplex; emballage/fardage; portée du PPAP et des tests. Commencer la collaboration: /products/custom-metal-frames/ · /products/welding-trolley-carts/ · /services/automatic-welding/

Normes & Conformité

Normes / certifications pertinentes & documentation fournie

- Soudage & géométrie: ISO 5817 (niveaux de qualité), ISO 2553 (symboles), ISO 13920 (tolérances de construction soudée), ISO 2768 m / f (général), AWS D1.1 où spécifié.

- Revêtement: ISO 8501 (préparation), ISO 12944 (catégorie de corrosion & système), ISO 2808 (Dft).

- Assurance qualité automobile: Éléments PPAP (Fai, Plan de contrôle, PFMEA, MSA, PSSP) livré dans le cadre du bon de commande.

FAQ

Q1: Quels matériaux conviennent le mieux aux patins automobiles et aux cadres agricoles?

Pour la rigidité et la rentabilité, Q355 / S355 est courant. Choisir 304/316 là où il existe un risque fréquent de lavage/corrosion; prendre 6061/6082 aluminium pour réduire la masse du chariot et la force de poussée.

Q2: Comment sélectionner les roulettes et vérifier la capacité de charge?

Utiliser 3-partage de charge de roulettes pour les tours et un 1.3–2,0 facteur de sécurité. Exemple: 800 kg charge utile ⇒ 800/3 ≈ 267 kg × 1.5 ⇒ sélectionner ≥400 kg roulettes évaluées; diamètre Ø150–200 mm dépend du plancher et des seuils.

Q3: Quelles tolérances puis-je appeler?

Les constructions standards répondent ISO 13920 B / c et ISO 2768 m / f. Conseils typiques: planéité ≤1,0–2,0 mm sur les blocs de référence; Connexion ≤ 1,5 mm / m. Des fonctionnalités plus serrées sont usinées.

Q4: Quelle classe de soudure proposez-vous?

Défaut ISO 5817 Classe C; classe B appliqué sur des joints visibles ou critiques. Référence structurelle: AWS D1.1 si le dessin l'exige.

Q5: Manteau électronique, zinc, ou de la poudre, qu'est-ce qui me convient?

Mapper l’environnement à ISO 12944: zinc pour la protection sacrificielle contre la corrosion, coat électronique pour la couverture des bords/cavités, poudre (70–100 μm) pour l'impact et la durabilité des couleurs. Duplex les systèmes prolongent la durée de vie en cas d'exposition sévère.

Q6: Pouvez-vous fournir la documentation PPAP?

Oui. Nous soutenons Fai, Plan de contrôle, PFMEA, MSA, PSSP, plus WPS / PQR, Coc, Rapports VT/DFT/NDT comme spécifié.

Q7: Qu'est-ce qui détermine le prix et les délais de livraison?

Longueur et classe de soudure, références usinées/PCD, spectre, revêtement duplex, et le coût et le calendrier de l'entraînement d'emballage/de fardage. Nous citons les plages après examen des dessins.

Télécharger le dessin / Obtenez un devis

Partagez vos dessins (ÉTAPE/DWG/PDF), charge utile et service (manuel/remorqué/train), système de finition, et toute portée PPAP/test. Nos ingénieurs vous renverront des notes de fabricabilité et un devis ferme.