Custom Welding Fabrication Manufacturer in China

With a track record of exporting around 200 containers annually to various countries worldwide while maintaining good QC standards and prompt delivery times, Able Hardware has established itself as an industry leader in metal fabrication manufacturing. Read More…

20+ years export manufacturing…

Robotic welding cells & fixture-based

CMM reports & PPAP basics

View More

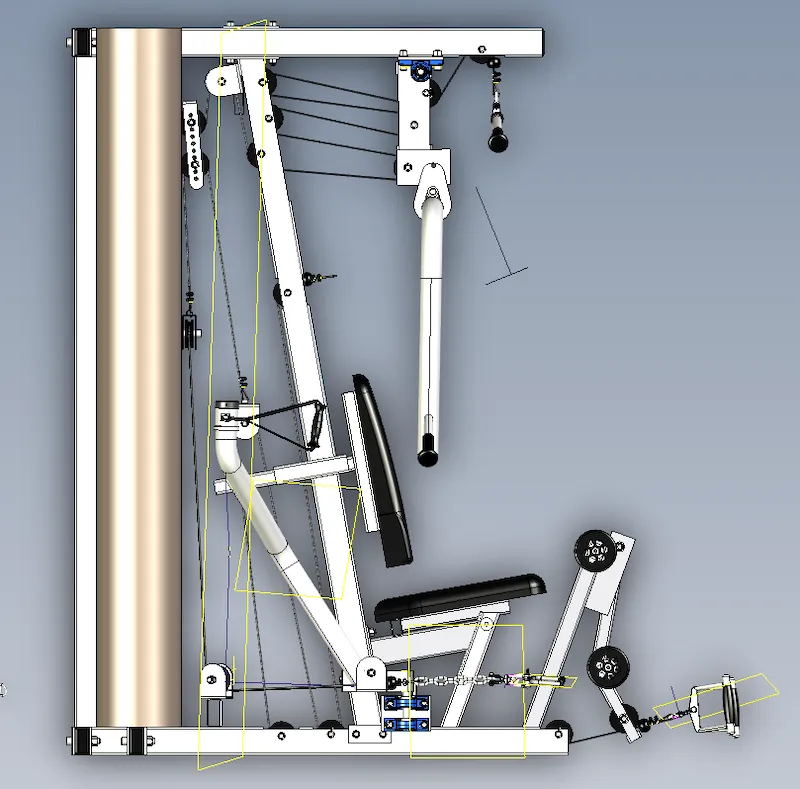

Custom Welding Fabrication Service

Robotic MIG Welding Services

Repeatable, fixture-based welding for steel tube frames, cart bases, and subframes

Laser Cutting & CNC Machining

Tube & sheet profiling, precision slots/holes, machining for welded assemblies.

Powder Coating & Finishing

Durable industrial finishes: powder, zinc, e-coat to match the environment.

As the founder of Able Hardware, I see organizational development as a critical component that has shaped our two-decade journey. It’s not just about adapting and innovating, but about embracing constant transformation with a firm adherence to our core values. In practice, one strategy we implemented is fostering a culture of continuous learning. Our teams are constantly encouraged to broaden their knowledge base, leading to an evolutionary improvement in our manufacturing processes over the years. Read More…

Jason Woo , founder of Able Hardware, explains the hurdles he faced with slow payment processing in his manufacturing business, particularly because of his complex global supply chain. He recalls one instance where a delayed ACH payment caused a shipment to be held up at customs, which led to expedited shipping fees and derailed his production schedules. Read More…

“As the founder of a successful metal fabrication business, one way that I’ve learned to decrease entrepreneurial risks is through robust supply chain management.

It’s crucial to ensure continuity in your supply chain to avoid disruptions that could harm your operations.

I achieved this through owning our raw material factories and maintaining diverse sourcing strategies.

Read More…

One notable instance was when a production team member suggested an improvement in our manufacturing workflow to reduce material wastage. This simple yet innovative idea led to significant annual savings for our company. Another successful initiative was the introduction of energy-efficient LED lighting throughout our factories, recommended by our maintenance staff. This has not only significantly slashed our energy bills but also improved the working conditions. Read More…

Why 1000+ Clients Rely on Able Hardware

Able Hardware’s custom metal fabrication services bring a host of advantages to various industries, businesses, and projects. Here’s why our clients trust us:

Cost-effective and Rapid Production

Our capabilities extend to swiftly crafting both metal prototypes and finished products, ensuring a quick turnaround without compromising on precision. The efficiency of our high-volume production processes translates into affordable sheet metal fabrication services for our clients.

Diverse Materials and Advanced Techniques

Our proficiency in a multitude of metal fabrication techniques empowers us to deliver complex components with intricate detailing. We offer an extensive selection of specialty alloy metals that are engineered to resist electrical interference, withstand high temperatures, and combat corrosion effectively.