Table of Contents

Overview & Use Cases

Why this solution for retail environments

Able Hardware designs and builds fixture frames and wire displays that stand up to daily retail traffic while presenting a clean, premium look on the sales floor. We combine automatic/robotic MIG for carbon steel with TIG where cosmetic stainless welds matter, then finish with controlled powder coating for batch-to-batch color consistency across international rollouts. KD (knock-down) construction, concealed fasteners, and signage-friendly details speed installation and simplify planogram updates.

Typical applications in retail (fixtures, displays, rolling racks)

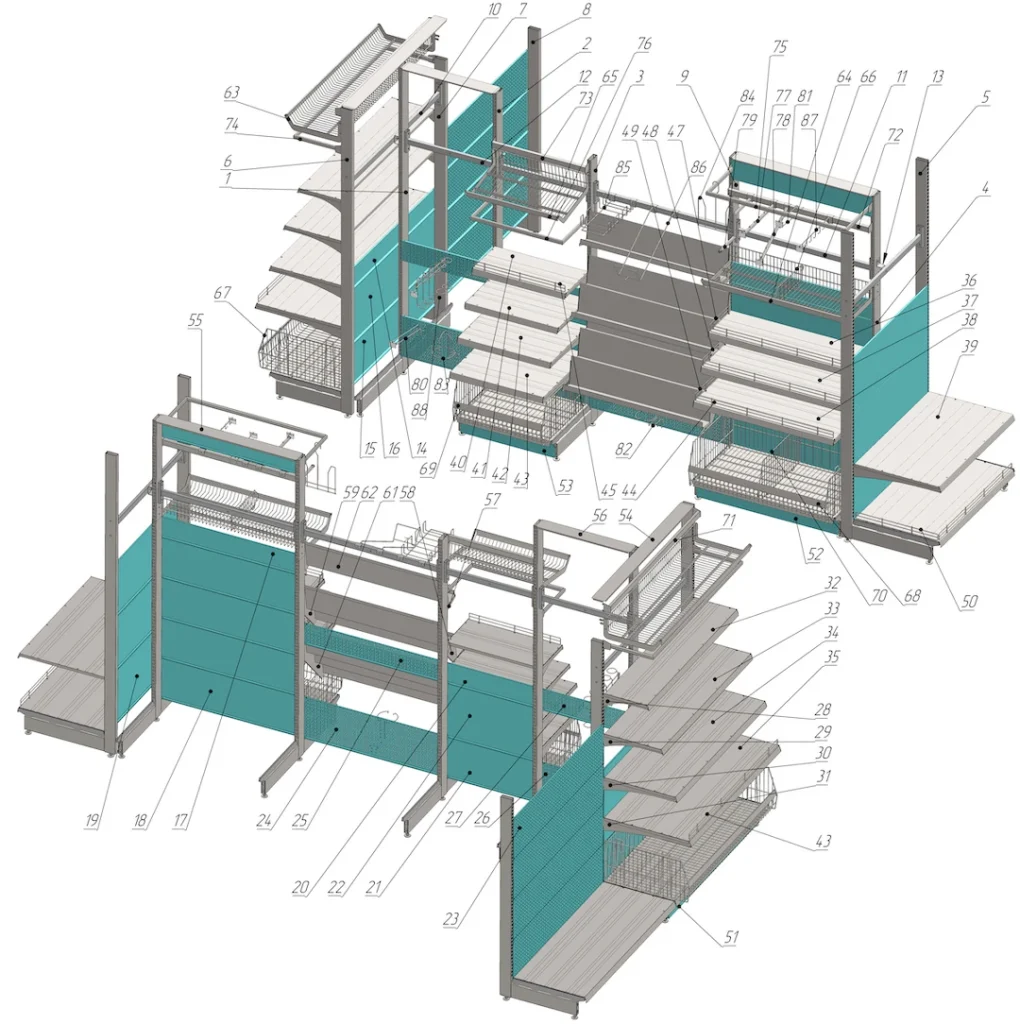

- Gondola bases/uprights, slotted panels, and shelf frames

- Wire shelves, baskets, dividers, and peg/slatwall accessories with 25–50 mm grid pitch

- A-frames and nesting tables for seasonal/promotional displays

- Rolling racks with low-noise casters for apparel and back-of-house movement

- Signage holders, price rails, tablet stands, and color-matched accessories

Technical Properties

Materials, profiles & loads; tolerances (ISO 13920/ISO 2768) & weld quality (ISO 5817)

- Materials & grades: Q235/S235 and Q355/S355 carbon steel for strength and value; 304 stainless for hygiene and FOH cosmetics.

- Profiles & thicknesses: RHS/SHS/angle/tube/wire/plate. Typical tubes 25×25×1.5 to 60×30×2 mm; plate 2–8 mm; wire Ø3–Ø8 mm. Grids in 25–50 mm pitch to meet loading and visibility needs.

- Dimensions & loads (typical bands):

- Gondolas: W 900–1200 × D 450–600 × H 1200–2100 mm, 10–80 kg per shelf depending on category.

- A-frames: W 1000–1600 × D 500–700 × H 1400–1800 mm.

- Nesting tables: L 900–1500 × W 600–900 × H 750–900 mm.

- Rolling racks: W 900–1500 × D 450–600 × H 1500–1800 mm; casters sized for manual rolling on tile/epoxy floors.

- Tolerances: ISO 13920 class B/C for welded constructions; ISO 2768-m/f for general dimensions. FOH geometry guidance includes panel flatness ≤1.0–2.0 mm and squareness ≤1.5 mm/m. Deburr and cosmetic edge radii per drawing.

- Weld quality & symbols: Visible joints to ISO 5817 Class B; hidden/structural joints to Class C. Symbols and callouts per ISO 2553.

Finishes & corrosion protection (ISO 12944/ISO 8501)

- Powder coat: RAL-matched systems at 70–100 μm DFT with gloss, matte, or texture options; batch records held for rollout consistency.

- Stainless 304: Brushed/grain-matched; weld discoloration removed for FOH presentation.

- Hardware: Zinc/e-coat as specified.

- Surface prep & selection: Steel prepared per ISO 8501; coating systems chosen for indoor ISO 12944 C1–C3 environments (sales floor to BOH).

Manufacturing Options

Automatic/robotic MIG (and TIG if specified), jigs & fixtures, repeatability

Robotic MIG cells standardize arc parameters and bead geometry on carbon steel frames, enabling stable takt times for high-volume programs. TIG is applied to 304 stainless or visible cosmetic joints. Custom jigs and datum pads control variation, while CNC-machined mounts enable fast, repeatable assembly in store or DCs.

Secondary ops: laser cutting, bending, machining; coating & KD packaging

Laser cutting produces price-rail windows, slots, and sign pockets; press-brake forming and wire forming shape brackets and baskets; CNC machining tightens critical interfaces. After finishing, fixtures are KD-packed with barcoded labels, illustrated assembly sheets, protective wrap, and corner guards; pallet densities are optimized to reduce freight cost and damage.

Types & Geometry

Common assemblies for retail (fixture frames, wire shelves/baskets, signage holders, rolling racks) & sizing bands

- Fixture frames: Tube-and-plate bases with slotted or pegboard back panels; hole patterns aligned to 25 or 50 mm increments for universal accessories.

- Wire shelves & baskets: Primary wires Ø4–Ø6 mm with cross wires Ø3–Ø4 mm; edge hems or rod stiffeners to meet 10–80 kg per-shelf targets. Anti-snag wire ends specified for apparel and soft goods.

- Signage holders: Laser-cut frames (A5–A1), bolt-on or magnetic brackets; concealed fasteners to maintain brand aesthetics.

- Rolling racks: H- or Z-base frames with toe guards, ergonomic handle height, and low-noise casters; optional ESD/grounding features for electronics retail.

Quality & Testing

What we verify (VT, DFT, dimensional/AQL cosmetics; optional PT/MT/RT) and documentation (WPS/PQR, CoC)

- 100% VT of welds; dimensional checks to ISO 2768/13920 with optional CMM on datum features.

- Cosmetic AQL tailored to FOH visibility zones.

- Coatings: DFT to ISO 2808, adhesion/cure checks, and gloss/texture comparison against master chips.

- Functional tests: Wobble/tilt stability, push/pull force feel, caster roll with fastener torque verification, and tip-stability notes for tall fixtures.

- Documentation: WPS/PQR for robotic/TIG welds; CoC, material certs, and inspection reports supplied per shipment.

Pricing & Lead Time

MOQ, pilot runs, indicative cost drivers (no hard prices)

We support pilot runs for NPI and scale to wholesale rollout volumes. Indicative cost drivers include: material grade (Q235/S235 vs Q355/S355 vs 304/6061), tube/wire size, total weld length and cosmetic class (ISO 5817-B vs C), laser features, coating color changes/DFT, caster specification, and KD density (pcs/pallet). Lead time improves with consolidated colors, shared jigs, and repeat releases. Provide drawings and annual volume for a responsive VE (value-engineering) quote.

Standards & Compliance

Relevant standards/certifications & documentation provided

- Welding: ISO 5817 (acceptance), ISO 2553 (symbols); AWS D1.1 used as reference if required by your standard library.

- Geometry/tolerances: ISO 13920 for welded constructions; ISO 2768-m/f for general features.

- Coatings: ISO 8501 for prep; ISO 12944 for indoor corrosion categories C1–C3.

- Material/finish declarations: RoHS/REACH statements for coating systems and hardware available on request.

FAQ

What wire diameters and grid pitches are common?

Ø3–Ø8 mm wire with 25–50 mm grid pitch, tuned to shelf load and product size.

Can you hit ISO 5817-B on visible welds?

Yes—FOH joints are built/finished to Class B; non-visible joints default to Class C for cost control.

What tolerances should we call out?

Use ISO 13920 B/C for welded frames and ISO 2768-m/f for general features; FOH targets include flatness ≤1.0–2.0 mm and squareness ≤1.5 mm/m.

How do you manage RAL color consistency?

Powder coat 70–100 μm DFT with retained master chips and batch records. We supply witness panels for sign-off and align gloss/texture per spec.

Is KD packaging standard?

Yes—flat-pack with labeled fasteners, barcodes, and assembly sheets; pallet counts planned to your DC standards.

What do you need for a quote?

Send STEP/DWG/PDF, target loads (kg), RAL color/gloss/texture, signage/peg/slatwall requirements, and annual volume. We’ll respond with VE options and lead-time ranges.

Upload drawing / Get a quote

Ready to refresh fixtures or launch a new display family? Upload your drawings and specs, note target loads, finish (RAL + gloss/texture), KD packaging needs, and rollout volumes. Able Hardware will return a manufacturable proposal with coating samples and a pallet-efficient packing plan.