Table of Contents

Overview: Our Approach to Welding Quality

At Able Hardware, “quality” is an engineered system—not a final inspection step. For robotic MIG-welded shelving, frames, and carts, we build quality into drawings, welding procedure control, operator qualification, in-process checks, and verification with clear, export-ready documentation. Units are metric throughout (mm, °C, N, μm).

What “export-ready QA” means for OEM/ODM buyers

Export-ready QA means you receive controlled welding procedures (WPS/PQR), qualified operators, traceable materials and finishes, dimensional/CMM data where needed, clear acceptance criteria (ISO 5817), and packaging that protects coatings and edges throughout international transit—plus documentation aligned with your PPAP/basic element expectations.

How this hub is organized (Documents · Standards · Testing)

Use this hub to navigate our quality content:

- Documents → see deliverables and templates in QA Documents

- Standards → acceptance levels, symbols, and weld classes in Weld Standards

- Testing → corrosion, NDT, and functional testing in Testing

Quality System & Certifications

We operate a formal quality management approach consistent with ISO 9001 (scope available upon request). Welding quality is aligned to ISO 3834 principles, with scope and depth defined by contract.

Welding quality requirements & process control (ISO 3834)

ISO 3834 guidance anchors our process control: contract review, WPS/PQR availability, consumable control, welder qualifications, calibrated gauges, and inspection planning. The level of control is tailored to your risk and compliance needs.

Procedures & personnel (WPS/PQR, ISO 15614-1/AWS D1.1, ISO 9606-1)

- WPS/PQR qualified to ISO 15614-1 (or AWS D1.1 when specified)

- Welder/operator qualification to ISO 9606-1

- Work instructions tied to part numbers, weld symbols, and acceptance levels

QA Documents We Provide

We document what we build so you can release parts faster with fewer questions.

COA, first-article, dimensional/CMM reports, PPAP basics

Deliverables can include: COA, in-process inspection sheets, FAI (first-article), dimensional/CMM or laser-scan reports, and PPAP basics (agreed element list such as Part Submission Warrant, control plan, FAI, capability where applicable).

Traceability, material/finish records & change control

We maintain traceability for materials, welding wire/lot (if requested), coatings, and finishing parameters. Change control ensures revisions are logged and approved prior to implementation.

Inspection & Measurement

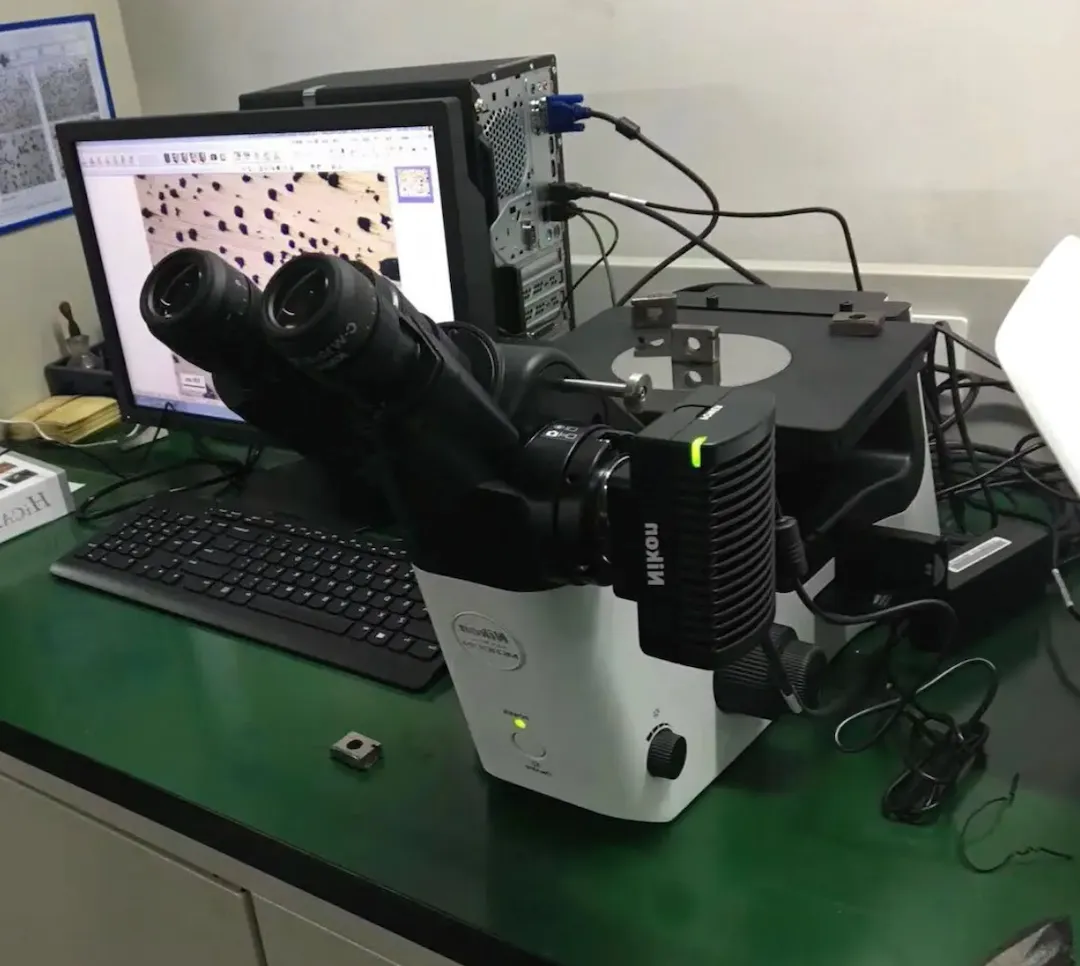

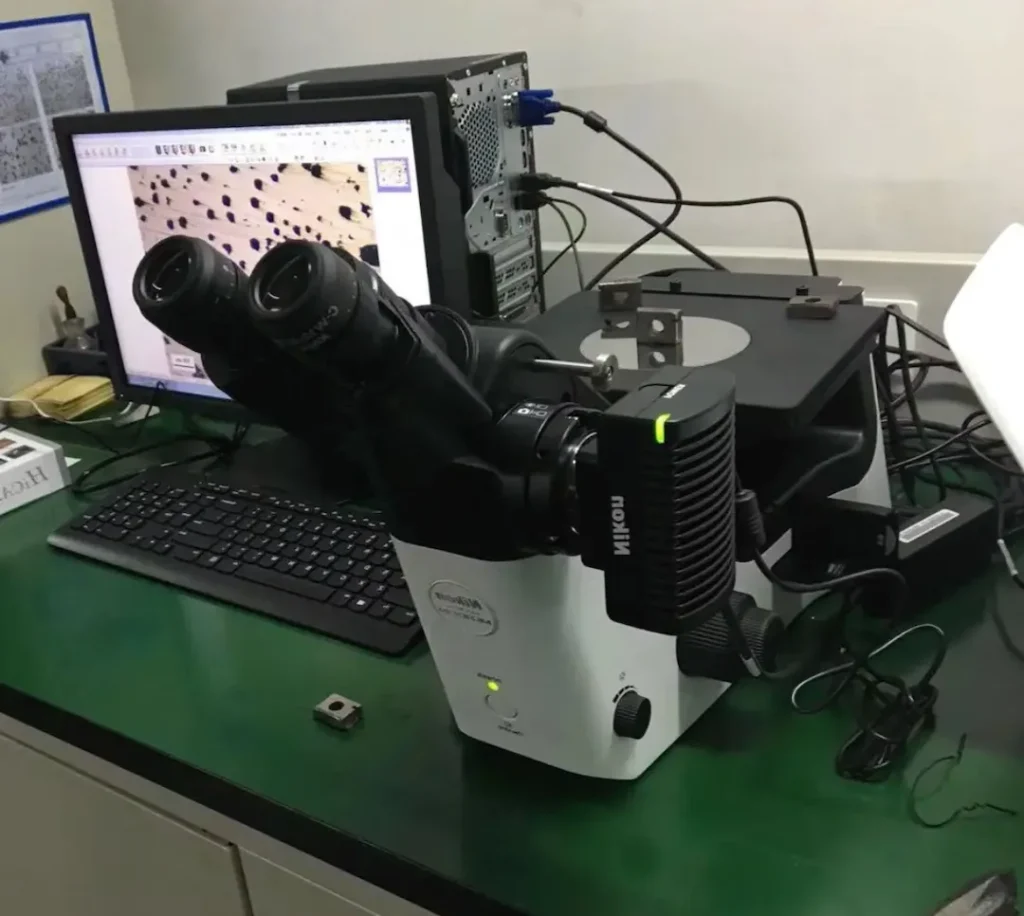

We combine visual checks with fixtures, gauges, and metrology to control geometry and finish.

Visual inspection (ISO 17637) & acceptance (ISO 5817)

Visual inspection follows ISO 17637; weld acceptance levels are defined by ISO 5817 (typically B or C as specified). Weld symbol definitions conform to ISO 2553 to avoid ambiguity.

Dimensional controls (fixtures/CMM), ISO 13920 & ISO 2768

- Checking fixtures and gauges for in-process control

- General welded tolerances per ISO 13920

- Machined features per ISO 2768

- Thermal cut quality per ISO 9013 (where applicable) For FA/PPAP, we can provide CMM or laser scan datasets.

Weld Standards & Acceptance

Clarity up front reduces rework and accelerates approvals.

Symbols & callouts (ISO 2553) and quality levels (B/C)

Drawings should use ISO 2553 symbols with legible size/length fillet callouts, throat sizes, intermittent patterns, and any contour requirements. Specify ISO 5817 quality level B (stringent) or C (general) by joint—especially on visible or high-load seams.

NDT options (MT/PT/UT/RT) per ISO 17638/17640/17636

When required by contract, we can coordinate NDT:

- MT (magnetic particle) / PT (penetrant) per ISO 17638

- UT (ultrasonic) per ISO 17640

- RT (radiographic) per ISO 17636 Scope, coverage, and acceptance criteria are defined with your quality team.

Testing & Validation

We validate coatings and function before shipment, with sampling plans as specified.

Corrosion/finish tests (ISO 9227, ASTM D3359/D4060)

- Salt spray (neutral) per ISO 9227 to agreed hour targets

- Adhesion per ASTM D3359

- Abrasion per ASTM D4060 (Taber)

- Paint thickness checks with calibrated gauges

Load/functional tests and sampling (ISO 2859-1)

For carts/frames, we can run static/dynamic load, cycle testing, and brake/holding tests. Sampling plans per ISO 2859-1 (AQL) may be applied where specified.

Packaging & Shipping Quality

Robust packaging preserves cosmetic and structural quality during global transit.

KD/nested methods, protection, ISPM-15, labeling & barcodes

We use KD/nested packing, edge/paint protection, and stretch/bubble wraps. ISPM-15 pallets/crates are available. Labels/barcodes (SKU, PO, revision) improve inbound accuracy for your warehouse teams. See Packaging & Shipping.

Export documentation and inspection checklists

Export packs include packing lists, photos, and inspection checklists. If requested, we align packaging to your inbound QC SOPs.

Supplier Readiness (PPAP Basics)

We support OEM/ODM onboarding with pragmatic documentation.

Element list by agreement (control plan, FAI, capability)

A PPAP basics set is agreed per part family: control plan, FAI, material certifications, and capability studies (as applicable). This reduces launch risk and speeds approval.

MSA/Gage R&R and periodic audits (as applicable)

When measurement risk is high, we conduct MSA/Gage R&R. Periodic process audits confirm continued compliance to agreed standards.

FAQ

Q1: What QA documents are standard?

COA, in-process sheets, FAI photos/dimensions, and dimensional/CMM reports when specified. PPAP basics available by agreement.

Q2: Which weld standards do you follow?

Symbols per ISO 2553; acceptance per ISO 5817 (B/C). Visual inspection per ISO 17637.

Q3: How are tolerances handled?

General welded tolerances follow ISO 13920; machined features follow ISO 2768. Thermal cut quality per ISO 9013.

Q4: Can you provide NDT?

Yes—MT/PT/UT/RT per ISO 17638/17640/17636, to the scope in your contract.

Q5: How do you validate coatings?

ISO 9227 salt spray (targets by agreement), ASTM D3359 adhesion, ASTM D4060 abrasion, and paint thickness checks.

Q6: Do you support PPAP?

Yes—PPAP basics (e.g., control plan, FAI, capability) per agreed element list.

Q7: What about packaging and traceability?

KD/nested packing with protection, ISPM-15 pallets, barcoded labels, and material/finish traceability.

Call to Action

Ready to align drawings, acceptance levels, and packaging for export-ready deliveries? Upload your drawing and get a quote:

Request A Quote

Related Quality Resources: