Table of Contents

Overview & Scope

Able Hardware’s weld standards hub explains how we specify, manufacture, and verify welds for custom welded shelving, frames, and industrial carts. We align drawings to ISO 2553 symbols, define acceptance using ISO 5817 weld quality levels (B/C/D), and—if requested—apply AWS D1.1 acceptance criteria for steel. Inspection follows ISO 17637 for VT and ISO 17635 for NDT rules, with sampling per ISO 2859-1. For robotic MIG welding, our procedures, personnel, and equipment conform to ISO 15614-1, ISO 9606-1, ISO 14732, ISO 17662, and the quality framework of ISO 3834. See our Quality Hub and related clusters: QA-Documents, Weld Standards, and Testing.

Why weld standards matter for welded shelving, frames & carts

Clear, referenced standards turn drawings into repeatable shop actions for shelving, frames, and carts alike. For shelving, they control upright squareness, shelf-beam fit, tab/slot and hole position, and weld profile so bays assemble quickly, stay flat under load, and remain interchangeable across production lots. For frames and carts, standards protect structural performance, caster plate alignment, and mating with machined brackets—reducing wobble, misfit, and field rework.

Using ISO 2553 symbols and ISO 5817 acceptance levels (plus AWS D1.1 when specified) ensures consistent interpretation from RFQ through PPAP. This tightens correlation between VT/NDT findings and functional risk, stabilizes robotic programs and fixtures, and minimizes distortion. The result is faster audits, fewer concessions, better cosmetic consistency for retail-visible shelving, and safeguarded export timelines—without overspecifying cost into the part.

How acceptance classes link to cost, risk, and repeatability

Tighter classes increase inspection scope, NDT coverage, fixturing complexity, and cycle time. Selecting “just tight enough” improves value: choose the class that meets function and risk without overspecifying.

Weld Symbols & Classes

ISO 2553 symbols and callouts used on drawings

We read and produce drawings per ISO 2553: arrow/other side notation; fillet, butt, plug, and seam symbols; intermittent patterns; and supplementary symbols (e.g., flush, convex). We expect weld size (a, z), length/pitch, and process notes (GMAW/MAG for MIG).

ISO 5817 acceptance levels (B/C/D) and when to choose each

- Level B (stringent): For critical load paths, tight fit-ups, or thin material where cosmetic and structural criteria are high.

- Level C (standard): The most economical, used for general structural frames and carts with robust safety factors.

- Level D (moderate): Non-critical brackets, guards, or fixtures where appearance and minor imperfections are acceptable.

Typical discontinuities controlled include excess reinforcement, undercut, porosity, cracks (never allowed), lack of fusion/penetration, and arc strikes.

Mapping to AWS D1.1 (if specified by project)

If a contract calls for AWS D1.1, we apply the applicable visual acceptance and (where required) clause-based NDT acceptance. While ISO 5817 and AWS D1.1 are not identical, we can map functional intent: e.g., ISO Level C for many general structural welds often aligns with AWS visual acceptance for statically loaded joints; we will confirm case-by-case in your RFQ.

Visual Inspection (VT)

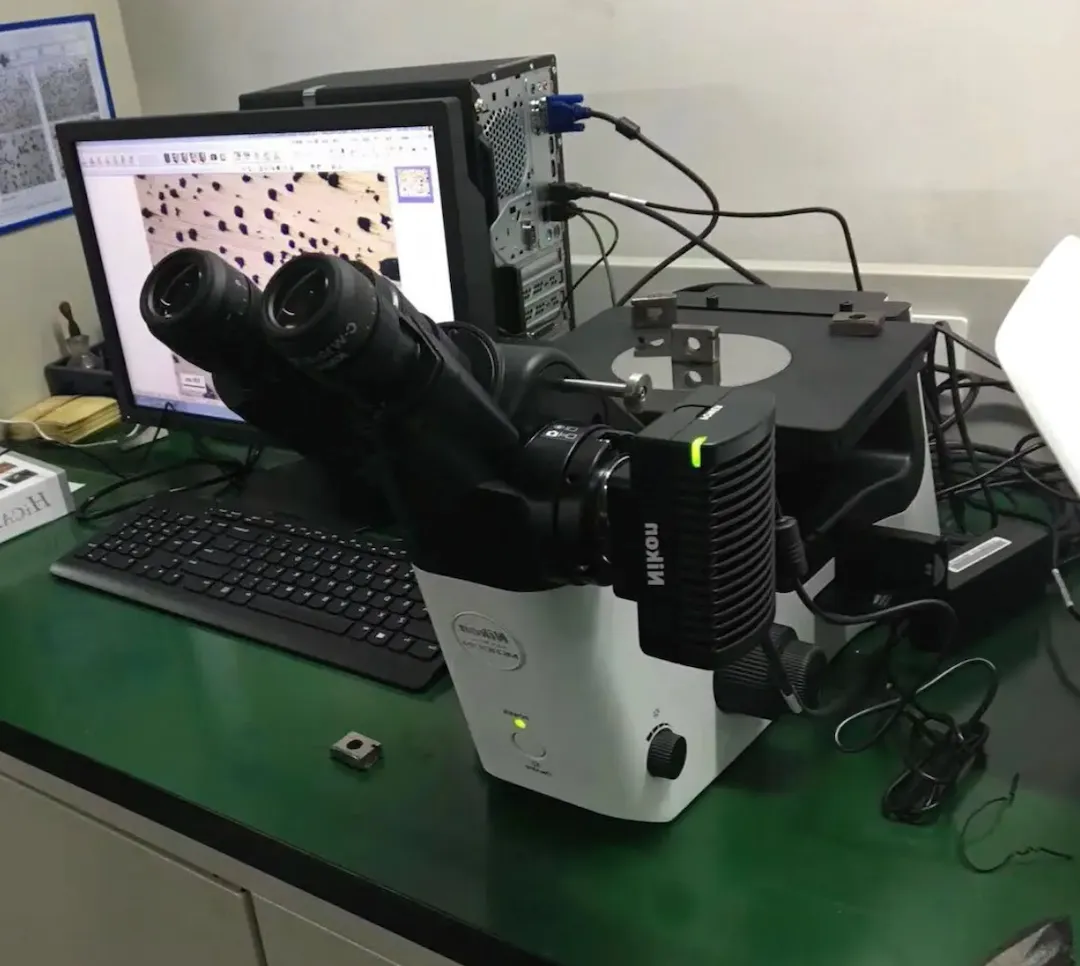

Method, lighting, gauges and typical defect categories (ISO 17637)

VT follows ISO 17637 with adequate lighting (≥500 lx), clean surfaces, and gauges for weld throat/leg size, fillet profile, and undercut depth. Typical categories: profile deviations, spatter, overlap, undercut, porosity indications, starts/stops, and arc strikes.

Sampling and acceptance (AQL per ISO 2859-1)

Unless 100% VT is specified, we propose ISO 2859-1 AQL sampling (e.g., General Inspection Level II, AQL 1.0–2.5 for cosmetic/structural VT depending on risk). We’ll confirm lot size, sample size code letters, and acceptance numbers in the control plan.

Typical VT records and photo evidence

We provide defect-coded VT logs with marked photos and weld ID traceability by fixture/program, shift, and operator/robot setter.

NDT Options & When to Use Them

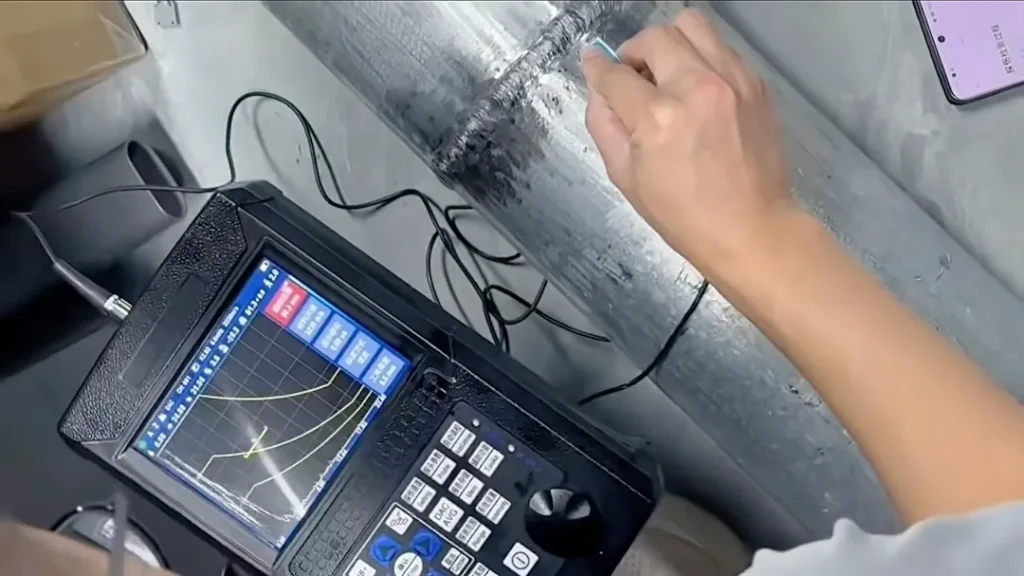

Dye penetrant (PT), magnetic particle (MT), ultrasonic (UT), radiographic (RT)

- PT – ISO 3452-1: Surface-breaking flaws on non-magnetic and stainless components.

- MT – ISO 17638 (acceptance ISO 23278): Surface/subsurface indications in ferromagnetic steels.

- UT – ISO 17640: Subsurface planar defects, thickness zones, and root fusion.

- RT – ISO 17636-1/2: Volumetric inspection for internal porosity/lack of fusion in butt welds.

Selection by risk/geometry, coverage, sensitivity, and cost

Use PT/MT for surface criticality or safety-relevant attachments; UT for thicker sections and root quality; RT for critical butt joints where geometry permits. Coverage (percentage or specific joints), sensitivity level, and accessibility determine cost and turnaround.

Reporting and acceptance references (ISO 3452-1, 17638/23278, 17640, 17636)

NDT reports include technique, coverage map, essential parameters, indications with location and size, acceptance standard, and disposition (accept/rework). We follow ISO 17635 as the overarching rule set.

Robotic Welding Standards & Process Control

Procedure & operator qualifications (ISO 15614-1, ISO 9606-1, ISO 14732)

Welding procedures are qualified per ISO 15614-1 (PQR) with derived WPS for production. Manual welders hold ISO 9606-1 qualifications, and robotic operators/setters are qualified per ISO 14732. See our Automated Robotic Welding Services.

Equipment calibration/verification (ISO 17662) and parameter logging

Power sources, wire feeders, and gas flowmeters are verified to ISO 17662. We log current, voltage, wire feed, travel speed, and heat input by program ID to support repeatability and root-cause analysis.

Fixture design, weld sequencing, distortion control, and repeatability

Dedicated jigs control datums, root gaps, and angularity. We optimize sequencing to minimize distortion and spatter, using clamping, symmetric passes, and interpass temperature control (°C). For thermal cut edges, we manage cut quality per ISO 9013 to ensure sound weld prep.

Dimensional Tolerances & GD&T Interface

General welded tolerances (ISO 13920) vs machined features (ISO 2768)

For fabricated frames, we adopt ISO 13920 (commonly Class B or C by agreement) for straightness, flatness, and angularity. Machined features, tapped holes, or post-op faces follow ISO 2768 (m/k) unless otherwise specified.

Datum strategy (A/B/C) and critical GD&T (flatness, perpendicularity, position)

We recommend a clear A/B/C datum scheme aligned to the fixture. Typical controls: frame flatness across mounting planes, hole position for caster plates, and perpendicularity of uprights to base. For functional fits, define position tolerances at MMC with gauge pin sizes.

How standards influence inspection method (fixtures/CMM)

We verify weldments on checking fixtures and use CMM for First Article and periodic audits. Dimensional reports call out measurement method, reference datums, and environmental conditions (°C).

Documentation & Traceability

What we provide (COA/OQA, CMM, PPAP basics) and submission timing

Per lot, we can supply COA/OQA; CMM dimensional results for FAI/periodic; and PPAP Level 2/3 (Control Plan, PFMEA, Dimensional Results, WPS/PQR, material and finish certs, PSW). Finish validation, when applicable: ISO 9227 salt spray, ASTM D3359 adhesion, ASTM D4060 abrasion, and coating thickness logs (μm). See more about our QA documents.

File formats (PDF + CSV/XLS) and naming convention

Standard deliverables are PDF with optional CSV/XLS data tables. Filenames include part no._rev_lot-date to align with your PLM.

Cost & Risk Considerations

How class (B/C/D), NDT scope, and sampling affect price/lead time

- Class: B > C > D in cost due to tighter prep, welding time, and rework thresholds.

- NDT: Adding PT/MT/UT/RT increases direct cost and queue time; specify coverage by risk.

- Sampling: Moving from AQL 2.5 to 1.0 reduces risk but raises inspection hours.

- Fixtures/Programs: Dedicated jigs and robot programs add one-time cost but reduce unit price at volume.

Practical guidance for specifying “just tight enough” acceptance

Start with ISO 5817 Level C + focused VT. Add MT/PT to safety-critical brackets and UT for thick primary joints. Reserve Level B for high-risk load paths or tight downstream assembly. Keep GD&T functional and gaugeable.

FAQ

Q1. Which weld class should I choose?

For most carts and frames, ISO 5817 Level C balances quality and value. Use B for critical load paths; D for non-critical attachments.

Q2. Do I need NDT if we have 100% VT?

VT finds surface clues; NDT (PT/MT/UT/RT) detects surface/subsurface defects. Add NDT where failure risk is high or geometry hides defects.

Q3. How are robotic welders qualified?

Procedures by ISO 15614-1; manual welders to ISO 9606-1; robotic operators/setters to ISO 14732. Equipment is verified per ISO 17662 with parameter logging.

Q4. How do tolerances interact with welding?

Use ISO 13920 for the welded body, ISO 2768 for machined features. Define A/B/C datums and critical GD&T for flatness, perpendicularity, and hole position.

Q5. What documentation will I receive?

COA/OQA, VT/NDT reports, CMM FAI/periodic, and PPAP Level 2/3 artifacts (Control Plan, PFMEA, WPS/PQR, material/finish certs, PSW).

Q6. Can you work to AWS D1.1?

Yes—if specified, we apply AWS D1.1 acceptance and note any ISO ↔ AWS equivalences in the control plan.

Q7. How is sampling defined?

By ISO 2859-1 (lot size, Level II recommended). We propose AQL targets by risk and confirm in your RFQ.

Call to Action

Upload your drawings with weld symbols, target ISO 5817 level, and any NDT/GD&T requirements. We’ll propose fixtures, sampling plans, and a control strategy aligned to value and risk. [Upload drawing / Get a quote] → /quality/qa-documents/

Request A Quote

Related Quality Resources: