Overview & Use Cases

Able Hardware engineers and manufactures custom material-handling carts and racks for warehouse, distribution center (DC), and 3PL operations. Built from structural steel tubes and plates with robotic MIG welding, our carts, dollies, order-pick trolleys, kitting racks, and pallet-sized platforms are optimized for payload, ergonomics, and lifecycle cost. We provide OEM/ODM and custom service for B2B buyers, combining upstream laser cutting, CNC machining, and export-ready QA.

Table of Contents

Why this solution for warehouse & logistics environments

Modern DCs demand durable equipment that rolls smoothly on real floors, resists impacts, and survives continuous duty cycles. Our designs start from the operating envelope—load (150–1,200 kg), duty (manual or tugged), aisle constraints, floor type (concrete/epoxy/tiles), and safety rules. Using jigs and fixtures, we hold tight squareness and flatness on deck assemblies so carts track straight and reduce push/pull forces. Powder-coated or plated finishes protect in humid or high-throughput environments, while standard caster patterns reduce maintenance.

Typical applications in warehouses, DCs, and 3PL operations

- Order-picking trolleys with adjustable shelves and scanner mounts

- Pallet dollies and skid platforms for inbound/outbound lanes

- Kitting carts and line-feed racks for cross-dock or light assembly

- Bulk platform trucks with removable corner posts

- Tugger carts (mother-daughter or train systems) for milk runs

Explore related offerings: Welding Trolley Carts, Custom Metal Frames, Automatic Welding, Laser Cutting & CNC Machining, Powder Coating, and our Engineering Resources.

Technical Properties

Materials, profiles & loads; tolerances & weld quality

- Materials & grades: Carbon steel Q235/S235 and Q355/S355; optional 304/316 stainless for hygiene areas; 6061/6082 aluminum for lightweight carts.

- Profiles & thicknesses: RHS/SHS, angle, channel, and plate. Typical tubes: 30×30×2 to 120×60×4 mm; plate: 4–20 mm depending on deck and caster plate loads.

- Dimensions & loads: Typical L×W×H 600×400×300 to 2000×1200×900 mm. Payload targets 150–1,200 kg depending on frame geometry, caster set, and duty cycle.

- Tolerances: ISO 13920 class B/C for welded constructions; ISO 2768-m/f for general dimensions. Guidance: deck flatness ≤ 1.0–2.0 mm; squareness ≤ 1.5 mm/m. Weld symbols per ISO 2553.

- Weld quality: ISO 5817 class C standard; class B available on visible or critical joints. Structural reference AWS D1.1 if required. See our ISO 5817 reference.

Finishes & corrosion protection

- Surface prep: Blast/clean to ISO 8501 grade as specified.

- Coatings: Powder coat (70–100 µm RAL), zinc plating, e-coat, or industrial paint per environment.

- Selection: Align to ISO 12944 category (e.g., C2–C4) based on humidity, chemicals, and cleaning cycles. DFT checks per ISO 2808.

Manufacturing Options

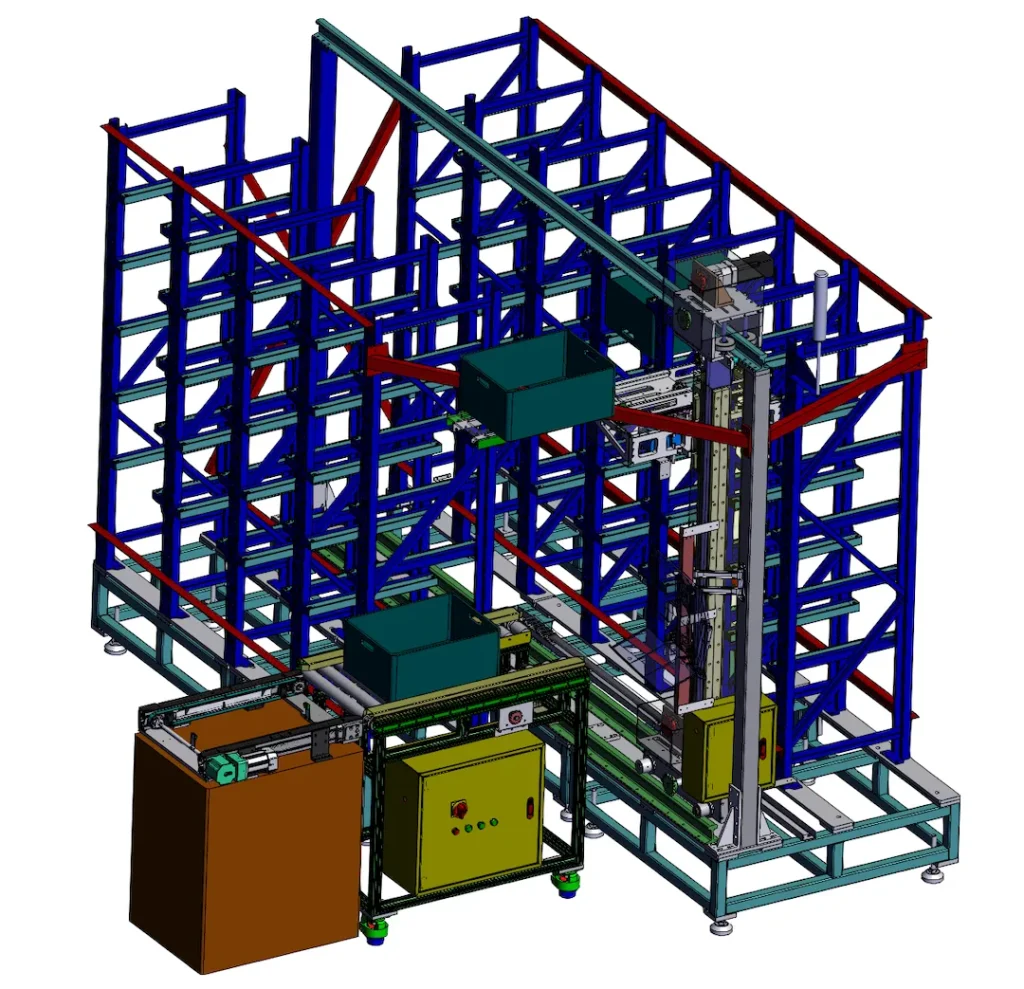

Automatic/robotic MIG (and TIG if specified), jigs & fixtures, repeatability

We weld frames using automatic/robotic MIG for speed and repeatability; TIG is used where stainless cosmetics or thin-gauge control is required. Custom jigs and locating pins ensure repeatable datums for caster plates and shelf posts across batches.

Secondary ops: laser cutting, bending, machining; coating & packaging

- Laser cutting & bending: Clean edges, accurate tabs/slots for self-locating assembly.

- CNC machining: Precision mounting holes and bearing seats.

- Coating: In-house or partner powder coating/plating with traceable batch records.

- Packaging & export: Palletized or crated with protective wrap, labels, and pcs/pallet optimized for container loading.

Types & Geometry

Common assemblies for warehouse & logistics (platform carts, order-pick trolleys, pallet dollies, rack frames) & sizing bands

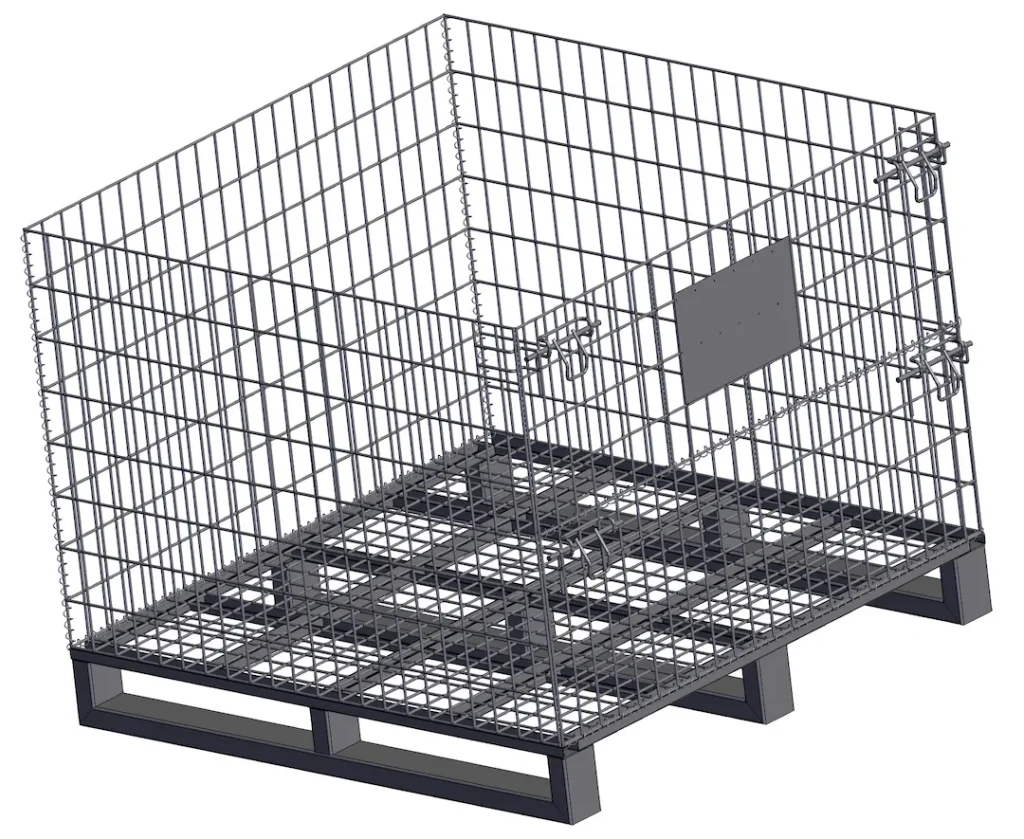

- Platform carts: 800×600 to 1600×800 mm decks; removable corner posts; toe guard rails.

- Order-pick trolleys: 2–4 shelves, 600×400 or 800×600 footprint, scanner/label mounts, ladder options.

- Pallet dollies: 1200×1000 and 1200×800 mm; fork-entry guards; tug eye or tow bar for trains.

- Kitting racks: Modular uprights with adjustable arms; anti-tilt features; footprint set by aisle width.

- Tugger “daughter” carts: Low-profile frames, central-lock casters, hitch geometry for smooth train articulation.

Caster engineering: Wheel materials PU/nylon/rubber/cast iron; diameters Ø100/125/150/200 mm; bearings (ball/roller/plain). Typical sets: 2 rigid + 2 swivel, or 4 swivel with brakes or a central lock. Load math: When turning, assume three casters share the load; choose a safety factor 1.3–2.0. Example: 800 kg payload + 80 kg cart ≈ 880 kg; per-caster design load ≈ (880/3)×1.5 ≈ 440 kg; select casters ≥ 440 kg each. Match tread to floor: PU for epoxy/tiles (low noise), nylon for heavy loads on smooth concrete, rubber for mixed floors.

Ergonomics & safety: Handle height suited to operator (typically 900–1100 mm), bump guards, corner protection, toe guards, and noise targets. Minimize push/pull forces by aligning wheelbase and bearing selection to route profiles.

Quality & Testing

What we verify (VT, DFT, dimensional checks; optional PT/MT/RT) and documentation (WPS/PQR, CoC)

- Visual inspection (VT) 100% for weld profile, spatter, undercut, and blending on hand points.

- Dimensional checks/CMM on caster plates and key datums; deck flatness and overall squareness per drawing.

- Coating DFT per ISO 2808 with recorded readings.

- Optional NDT: PT/MT/RT for critical welds as specified.

- Documentation: WPS/PQR if applicable, welder qualifications, CoC, and inspection reports aligned to PO.

Pricing & Lead Time

MOQ, sample policy, indicative cost drivers (no hard prices)

- MOQ: Typically 50–200 pcs per model depending on size and coating.

- Samples: Prototype in 7–15 working days after drawing sign-off; refundable tooling by agreement.

- Lead time: Production 25–40 days + transit, subject to coating and part count.

- Cost drivers: Steel grade and thickness; caster type/diameter and central-lock systems; weld class (ISO 5817 B vs C); finish (powder DFT, multi-coat systems); jig complexity; packaging density (pcs/pallet) and export requirements. Request a target budget range and annual volume so we can engineer the frame and caster set for the lowest total cost of ownership.

Standards & Compliance

Relevant standards/certifications & documentation provided

- Welding: ISO 5817 (quality levels), ISO 2553 (symbols); reference AWS D1.1 for structural criteria if required.

- Fabrication tolerances: ISO 13920 (welded constructions), ISO 2768-m/f (general).

- Coatings: ISO 8501 (prep), ISO 12944 (corrosion protection).

- Quality records: WPS/PQR, welder quals, inspection & DFT reports, CoC available with shipment.

FAQ

Q1: Which materials do you recommend for DC carts?

Q235/S235 for standard duty; Q355/S355 for higher payloads; 304/316 stainless for hygiene; 6061/6082 aluminum when weight reduction or manual handling is critical.

Q2: How do we select casters and verify load?

Size by worst-case turning load (three casters carrying) with a 1.3–2.0 safety factor. Choose Ø150–200 mm for tugged or rough floors; PU for low noise on epoxy, nylon for heavy loads on smooth concrete.

Q3: What tolerances can you hold on frames?

ISO 13920 class B/C with ISO 2768-m/f; typical deck flatness ≤ 1–2 mm and squareness ≤ 1.5 mm/m using jigs and controlled weld sequencing.

Q4: What weld class do you supply?

ISO 5817 class C as standard; class B for visible or critical joints. Weld symbols per ISO 2553.

Q5: Which coatings are suitable?

Powder coat 70–100 µm (RAL) for most DCs; zinc plating or e-coat for abrasion/corrosion resistance; specify ISO 12944 environment category.

Q6: What is the usual MOQ and lead time?

MOQs start at 50–200 pcs; lead time 25–40 days after sample approval. Urgent batches can be split-ship by agreement.

Q7: What drawings do you accept?

STEP/IGES/SolidWorks and annotated PDFs with critical datums, weld class, tolerances, and coating spec. We can assist via our Engineering Resources.

Upload your RFQ to start

Send your 3D/2D files and requirements (payload, floor type, duty cycle, finish, caster spec). We’ll engineer a cost-effective cart or rack set for your lanes.